QMX6025M Double-End Profiling Machine

Description:

The QMX6025M is a high-precision double-end profiling machine designed for edge milling and grooving operations on various solid wood and engineered wood components. It offers excellent speed, power, and flexibility, making it ideal for large-scale furniture and door production lines.

Key Features:

-

Max. Machining Width: 2500 mm

-

Processing Thickness: 10–120 mm

-

Feeding Speed: 6–36 m/min

-

Cutting Motor Power:

-

Sawing: 2 × 7.5 kW

-

Grooving: 2 × 3.0 kW

-

Spindle: 2 × 7.5 kW

-

-

Spindle Speeds:

-

Grooving: 7500 r/min

-

End Sawing: 3000 r/min

-

-

Highly adjustable angle cutting (saw blade ±20–45°, milling cutter ±25–45°)

-

Heavy-duty structure ensures stability and long service life

-

External Dimensions: 4880 × 4130 × 1890 mm

-

Total Weight: Approx. 6000 kg

Application:

Perfect for profiling, grooving, and edge processing of long panel components such as cabinet sides, door edges, and furniture frames. Suitable for high-volume production environments requiring precise and efficient machining on both ends.

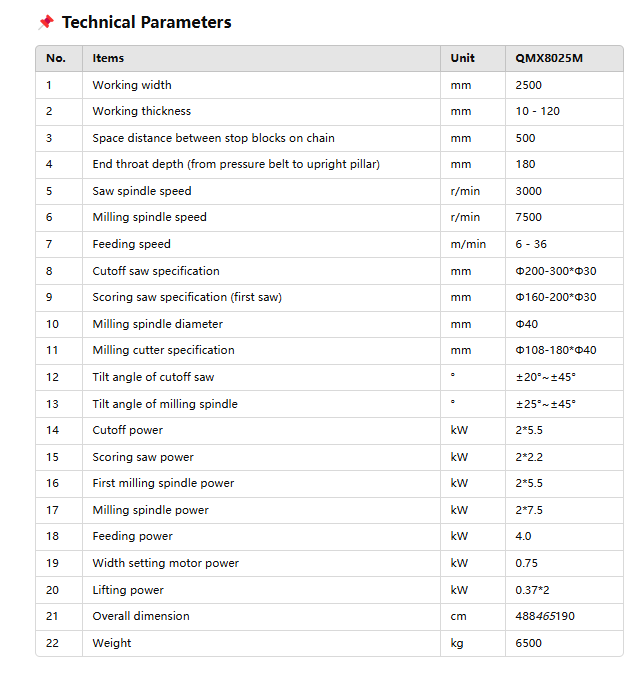

| No. | Items | Unit | QMX8025M |

|---|---|---|---|

| 1 | Working width | mm | 2500 |

| 2 | Working thickness | mm | 10–120 |

| 3 | Space between stop blocks on chain | mm | 500 |

| 4 | End throat depth (pressure belt to upright pillar) | mm | 180 |

| 5 | Saw spindle speed | r/min | 3000 |

| 6 | Milling spindle speed | r/min | 7500 |

| 7 | Feeding speed | m/min | 6–36 |

| 8 | Cutoff saw specification | mm | Φ200–300×Φ30 |

| 9 | Scoring saw specification (first saw) | mm | Φ160–200×Φ30 |

| 10 | Milling spindle diameter | mm | Φ40 |

| 11 | Milling cutter specification | mm | Φ108–180×Φ40 |

| 12 | Tilt angle of cutoff saw | ° | ±20°–±45° |

| 13 | Tilt angle of milling spindle | ° | ±25°–±45° |

| 14 | Cutoff power | kW | 2×5.5 |

| 15 | Scoring saw power | kW | 2×2.2 |

| 16 | First milling spindle power | kW | 2×5.5 |

| 17 | Milling spindle power | kW | 2×7.5 |

| 18 | Feeding motor power | kW | 4.0 |

| 19 | Width setting motor power | kW | 0.75 |

| 20 | Lifting motor power | kW | 0.37×2 |

| 21 | Overall dimensions | cm | 488×465×190 |

| 22 | Machine weight | kg | 6500 |

Model Comparison: QMX6025GK vs QMX6025MK vs QMX6025M

| Feature | QMX6025GK | QMX6025MK | QMX6025M |

|---|---|---|---|

| Function | Specialized for Three-Spine Buckle Male Tenon processing | Combines male tenon + insert slot cutting in one unit | Standard double-end edge profiling machine |

| Processing Width | 300–2500 mm | 300–2400 mm | 2500 mm |

| Processing Thickness | 10–60 mm | 10–60 mm | 10–120 mm |

| Cutting Speed | 6000–12000 rpm (Pre-cut), 4500–9000 rpm (Milling) | 6000–12000 rpm (Tenon + Insert Slot) | 7500 rpm (Milling), 3000 rpm (Sawing) |

| Key Tools | V-groove + Male Tenon Cutters | Male Tenon + Insert Slot Cutters | Edge milling, bevel cutting, tenoning |

| Feeding Speed | 3–36 m/min | 3–36 m/min | 6–36 m/min |

| Vacuum Suction Port | φ120×8 | φ120×6 | φ120×6 |

| Machine Size (L×W×H) | 485×465×182 cm | 500×465×182 cm | 488×413×189 cm |

| Machine Weight | 6500 kg | 6300 kg | 6000 kg |

| Application | High-precision male tenon machining for flooring and furniture | Integrated production of both tenon and slot for Three-Spine Lock | General wood edge profiling and bevel cutting |

| Best For | Lock flooring, engineered panel tenons | Full Three-Spine buckle production lines | General furniture & flooring factories |

Recommendation by Use Case

| Use Case | Recommended Model |

|---|---|

| Three-Spine buckle (male tenon only) | QMX6025GK |

| Complete three-spine processing (tenon + slot) | QMX6025MK |

| Standard double-end edge profiling & beveling | QMX6025M |