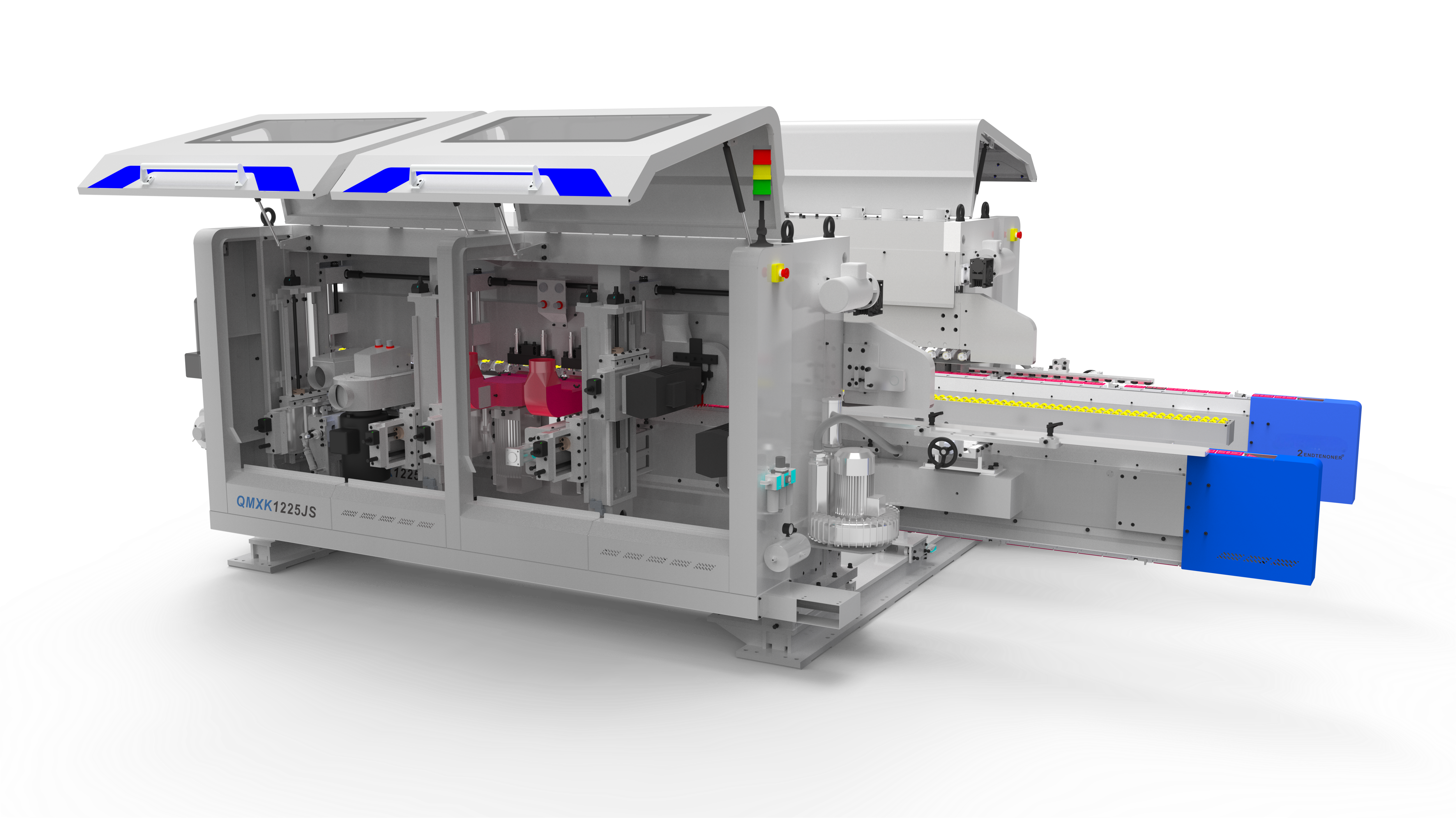

Key Advantages of the QMX1225JS CNC Double-End Saw Milling Sanding Machine

-

All-in-One Integrated Functionality

The QMX1225JS combines sawing, milling, and sanding in a single system, streamlining production and reducing the need for multiple machines. -

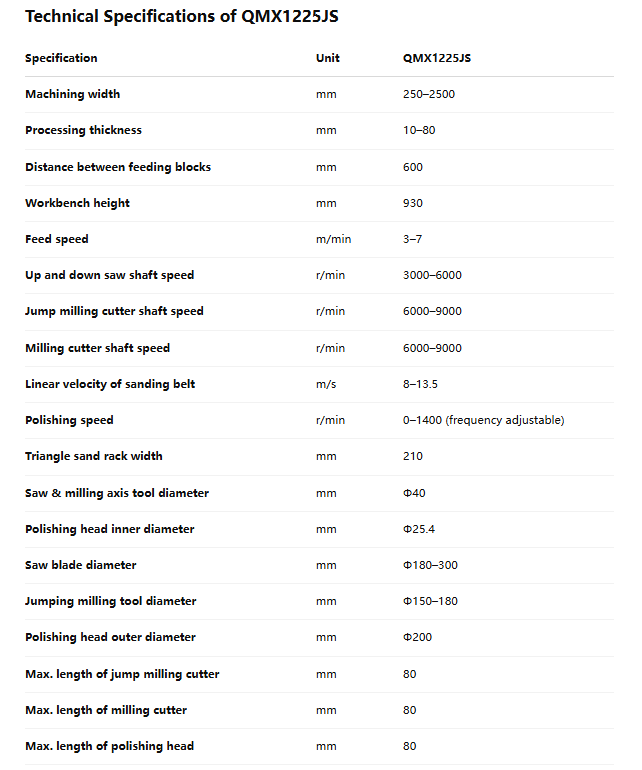

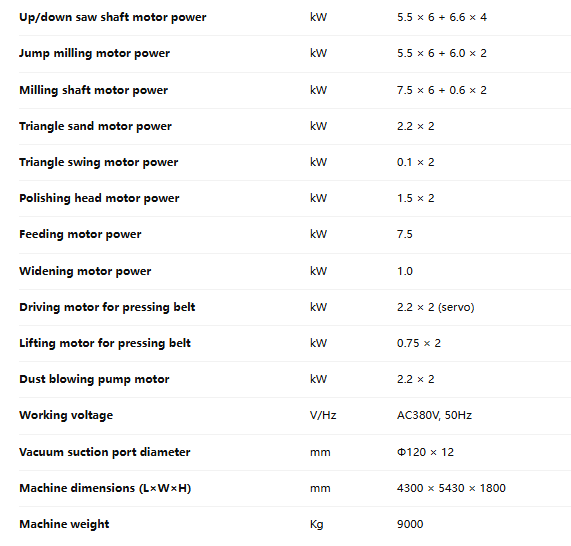

Wide Processing Range

The machine supports panel widths from 250mm to 2500mm and thicknesses from 10mm to 80mm, making it ideal for a variety of wood-based materials. -

High-Speed, Adjustable Operations

The QMX1225JS is equipped with high-speed cutter shafts (up to 9000 r/min) and adjustable polishing speeds (up to 1400 r/min), allowing for flexible, high-efficiency processing. -

Heavy-Duty Motor System

With multiple powerful motors—including 7.5kW × 6 for milling and 5.5kW & 6.6kW jump cutting motors—this machine is built for continuous industrial workloads. -

Precision Through CNC Control

Thanks to its numerical control system, the QMX1225JS ensures accurate cutting, stable tool positioning, and consistent processing quality. -

Enhanced Dust Collection System

Equipped with 12 large vacuum ports (Φ120) and dual dust-blowing motors, the QMX1225JS keeps your workspace clean and your equipment in top shape. -

Industrial-Grade Structure

The machine’s 9000kg solid frame minimizes vibrations and increases stability, ensuring precision even during high-speed operation. -

Optimized for Mass Production

Designed with high feed speed (3–7 m/min) and servo-driven pressure belts, the QMX1225JS is perfect for automated production lines in large factories.

Who Should Use This Machine?

-

Furniture Manufacturers

-

Especially those producing panel-based furniture, doors, or cabinets.

-

Perfect for creating high-quality edges and polished finishes.

-

-

Wood Processing Plants

-

For large-scale production lines processing MDF, particleboard, plywood, or solid wood panels.

-

-

Flooring and Door Companies

-

Ideal for manufacturers of wooden flooring, decorative panels, and custom-sized door panels.

-

-

Export-Oriented Factories

-

Especially those who require consistent high finish quality for international clients.

-