Key Advantages of the QMB620AT

-

Full 6-Spindle Configuration

Provides comprehensive four-side planing and profiling with additional upper/lower spindle flexibility for more complex shaping tasks. -

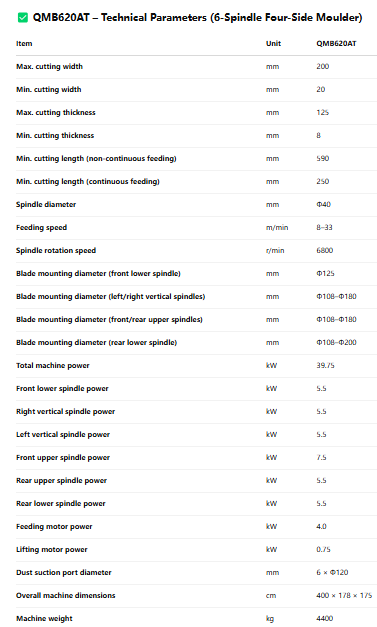

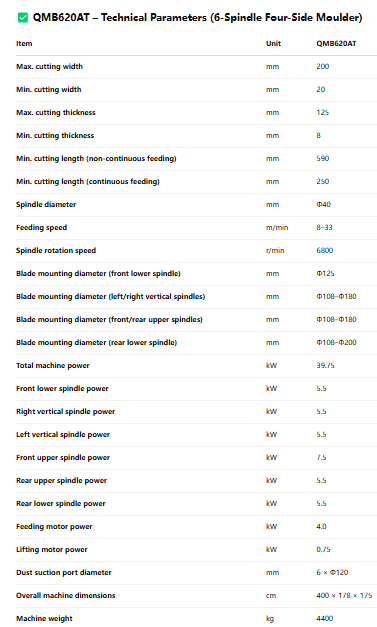

Wide Processing Capability

Can process material from 20mm to 200mm in width and up to 125mm thick, suitable for both small and large wood stock. -

High-Speed Precision

All spindles operate at 6800 r/min, ensuring a clean, smooth finish at high feed speeds of 8–33 m/min. -

Heavy-Duty Cutting Performance

With a total power of nearly 40 kW and individual spindle motors up to 7.5 kW, the QMB620AT is built for demanding, long-term operation. -

Short Piece Friendly

Equipped to process pieces as short as 250mm (with continuous feeding), making it ideal for trim, mouldings, and small furniture parts. -

Efficient Dust Management

Comes with 6 large Φ120 mm suction ports for efficient chip extraction, keeping your workspace clean and safe. -

Compact but Powerful

Its overall dimensions and 4400 kg weight provide stable operation while still fitting within many standard factory layouts.

Who Should Use the QMB620AT?

-

Furniture Manufacturers

Especially for high-precision shaping of door frames, window components, chair legs, table edges, etc. -

Wood Flooring & Trim Producers

Ideal for mass-producing mouldings, skirting boards, flooring boards, and decorative edges. -

Solid Wood Processing Plants

For companies needing to plane and profile wood on all four sides with consistent accuracy. -

Custom Woodworking Workshops

Those who produce high-end or detailed components and require speed, power, and flexibility in one compact system.