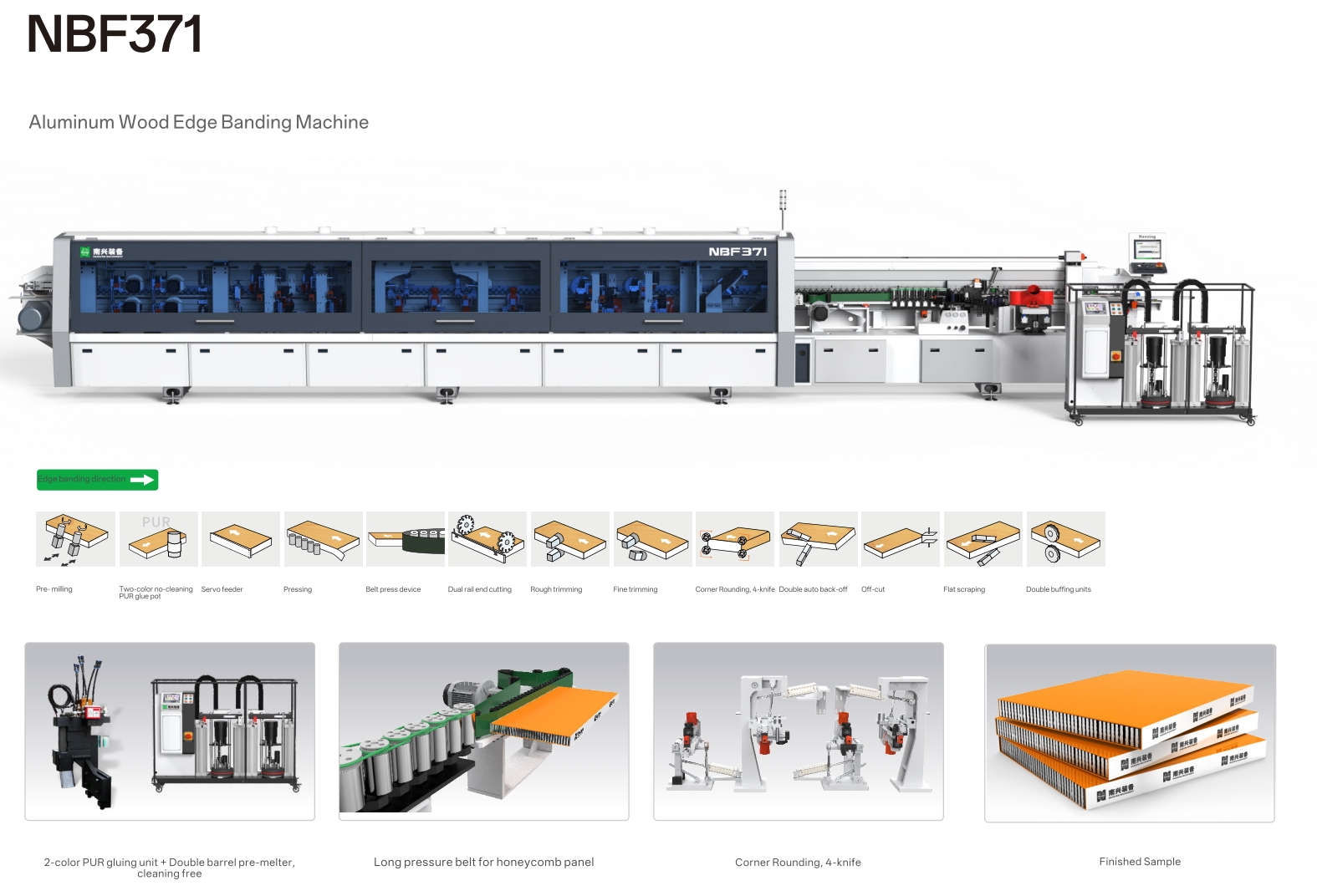

NBF371 Aluminum Wood Edge Banding Machine

The NBF371 is an advanced edge banding solution engineered for aluminum-wood composite panels and honeycomb structures. It is equipped with a high-precision 4-knife corner rounding unit, dual PUR gluing system, and a long belt press mechanism, ensuring strong adhesion, perfect finishes, and high-speed processing for even the most complex lightweight materials.

Key Features

-

Specialized for Aluminum-Wood Panels

Designed to handle both aluminum edge and wood core composite panels, especially honeycomb structures. -

2-Color PUR Gluing System

Supports fast switching between two PUR types; double-barrel pre-melter enables non-stop production and cleaning-free operation. -

Long Belt Press for Honeycomb Panels

Provides extended and even pressure distribution to ensure full bonding on lightweight, non-solid cores. -

Dual Rail End Cutting and 4-Knife Corner Rounding

Guarantees a seamless finish on thick or irregular edges, improving strength and appearance. -

Comprehensive Processing Flow

Includes pre-milling, servo feeding, gluing, pressing, trimming, back-off, off-cut removal, flat scraping, and double buffing for complete high-quality edge finishing. -

High Compatibility

Ideal for aluminum panels, composite doors, lightweight furniture, and metal-accented architectural surfaces.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NBF371 |

| Min. Workpiece Size | 120×80 mm |

| Workpiece Thickness | 9–60 mm (regular) / 9–22 mm (honeycomb) |

| Edge Tape Thickness | 0.4–3 mm (regular) / 1–2 mm (honeycomb) |

| Feeding Speed | 12 / 16 / 20 m/min (regular) / 12 / 16 m/min (honeycomb) |

| Total Power | 30 kW |

| Net Weight | 6210 kg |

Applications

Ideal for aluminum-wood hybrid furniture, honeycomb lightweight doors, cabinet panels with metal trim, and structural panels requiring durable, seamless, and heat-resistant edge finishes. Widely used in aerospace-inspired furniture design, high-end architectural interiors, and modern modular systems.