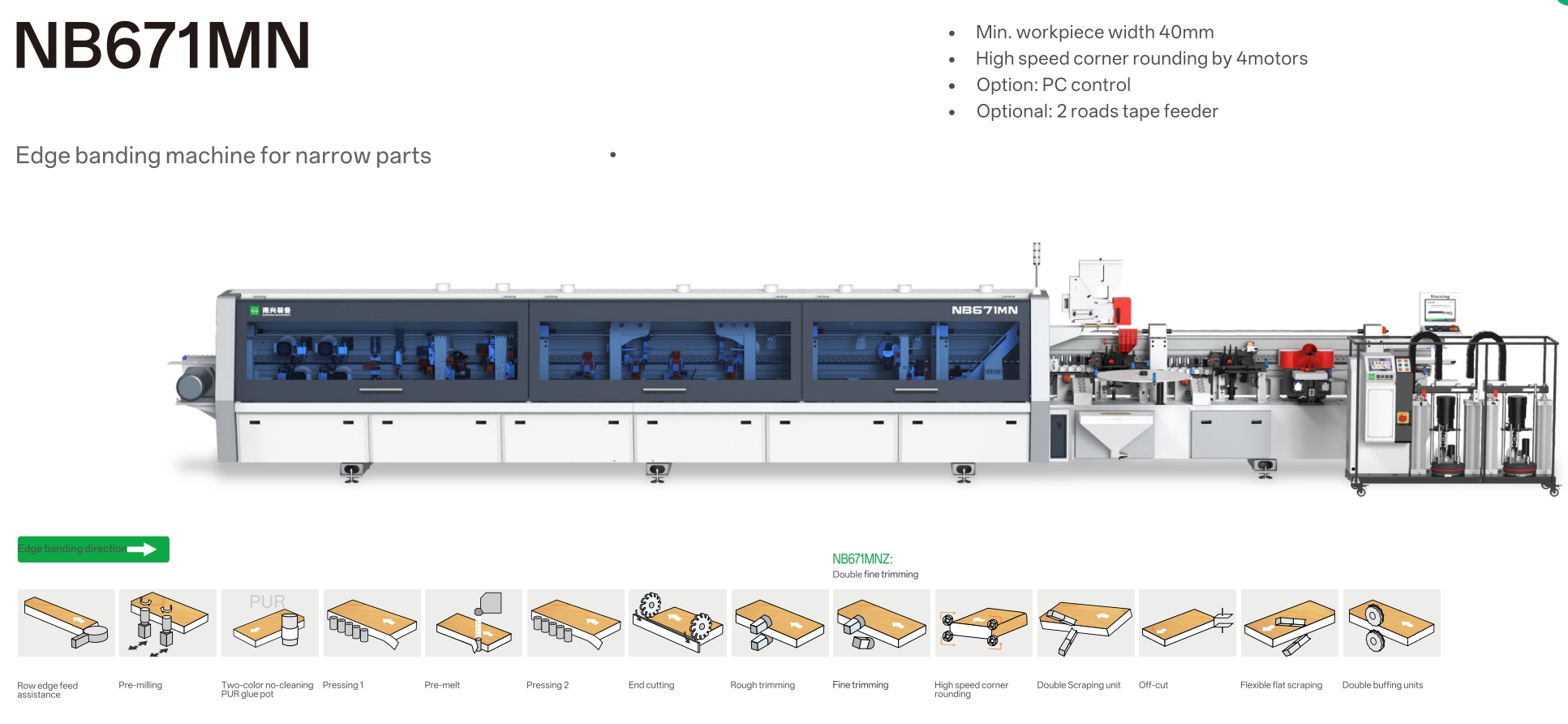

NB671MN Edge Banding Machine for narrow-width panels

The NB671MN is a high-performance edge banding machine specifically engineered for narrow-width panels. With a minimum workpiece width of just 40mm, it is ideal for cabinet frames, narrow decorative boards, and slim interior panels. This model offers compact, high-speed edge processing while maintaining excellent precision and reliability.

Key Features

-

Optimized for Narrow Parts

Supports minimum workpiece width of 40mm, suitable for high-precision slim board edge banding. -

High-Speed Corner Rounding

Equipped with a 4-motor system for fast and accurate corner rounding. -

PUR Glue Pot Integration

Supports two-color no-cleaning PUR glue application, delivering strong adhesion and resistance to water and heat. -

Comprehensive Edge Processing Units

Includes pre-milling, dual pressing, pre-melt, trimming, rounding, scraping, and double buffing for complete finishing. -

Flexible Control Options

Optional PC control system and 2-roads tape feeder for enhanced operational flexibility. -

NB671MNZ Upgrade

Offers double fine trimming for enhanced edge precision and appearance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NB671MN / NB671MNZ |

| Workpiece Length | ≥120 mm |

| Workpiece Width | ≥40 mm |

| Workpiece Thickness | 9–60 mm |

| Edge Tape Thickness | 0.4–3 mm |

| Min. Workpiece Size | 200×40 mm (with support plate: 200×60 mm) |

| Feeding Speed | 18/22/26 m/min (adjustable) |

| Total Power | 33.7 kW |

| Net Weight | 2950 kg |

| Overall Dimension | 10400×1050×1850 mm |

Applications

Ideal for the furniture and interior decoration industries, especially for processing narrow cabinet doors, drawers, frames, and linear decorative panels requiring high edge finish and durability. Suitable for PVC, ABS, acrylic, and PUR tape edge banding.