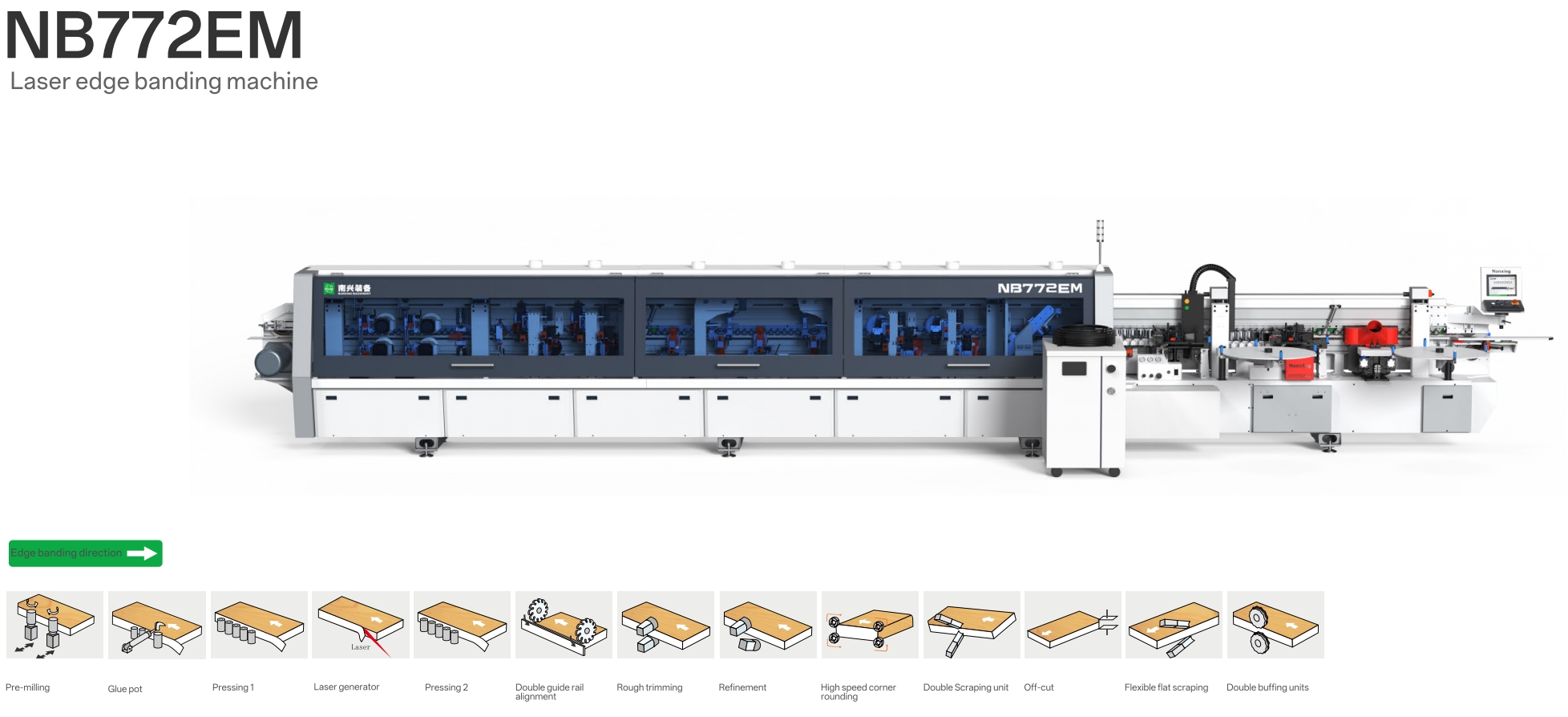

NB772EM Laser Edge Banding Machine

The NB772EM is a next-generation laser edge banding machine that combines traditional glue application with cutting-edge laser technology. This hybrid solution provides exceptional bonding strength and edge quality, making it ideal for manufacturers who prioritize flexibility, precision, and aesthetics in edge processing.

Key Features

-

Dual Bonding System (Glue Pot + Laser Generator)

Supports both traditional glue application and seamless laser bonding, offering greater material compatibility and process flexibility. -

High-efficiency Processing Units

Integrated modules include pre-milling, glue pot, laser head, pressing stations, dual rail alignment, rough and fine trimming, high-speed corner rounding, double scraping units, off-cut, flexible flat scraping, and dual buffing units. -

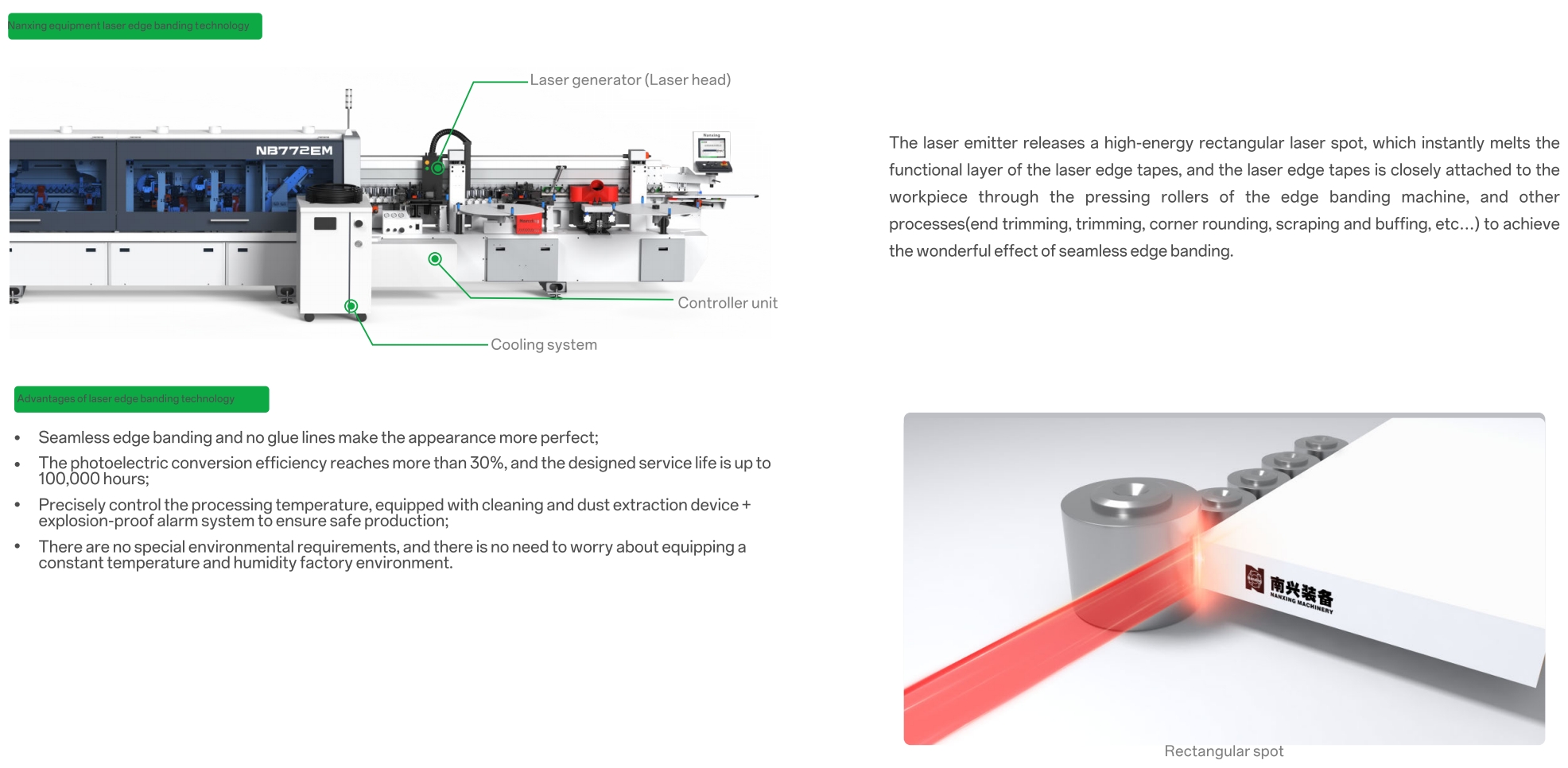

Intelligent Laser Edge Bonding

Laser emitter produces a high-energy rectangular beam that melts the adhesive layer of laser edge tapes, achieving perfect adhesion without visible glue lines. -

Precision Control System

Temperature, cleaning, and dust extraction are monitored and managed via the explosion-proof alarm system, ensuring safe and stable operation. -

Environmentally Adaptive

No special factory conditions required — operates reliably in standard factory environments without temperature or humidity control.

Advantages of Laser Edge Banding

-

Seamless edge finishing with no visible glue

-

Over 30% photoelectric conversion efficiency

-

Laser module designed for up to 100,000 hours of service life

-

Explosion-proof safety system for temperature and dust control

-

Suitable for diverse manufacturing environments

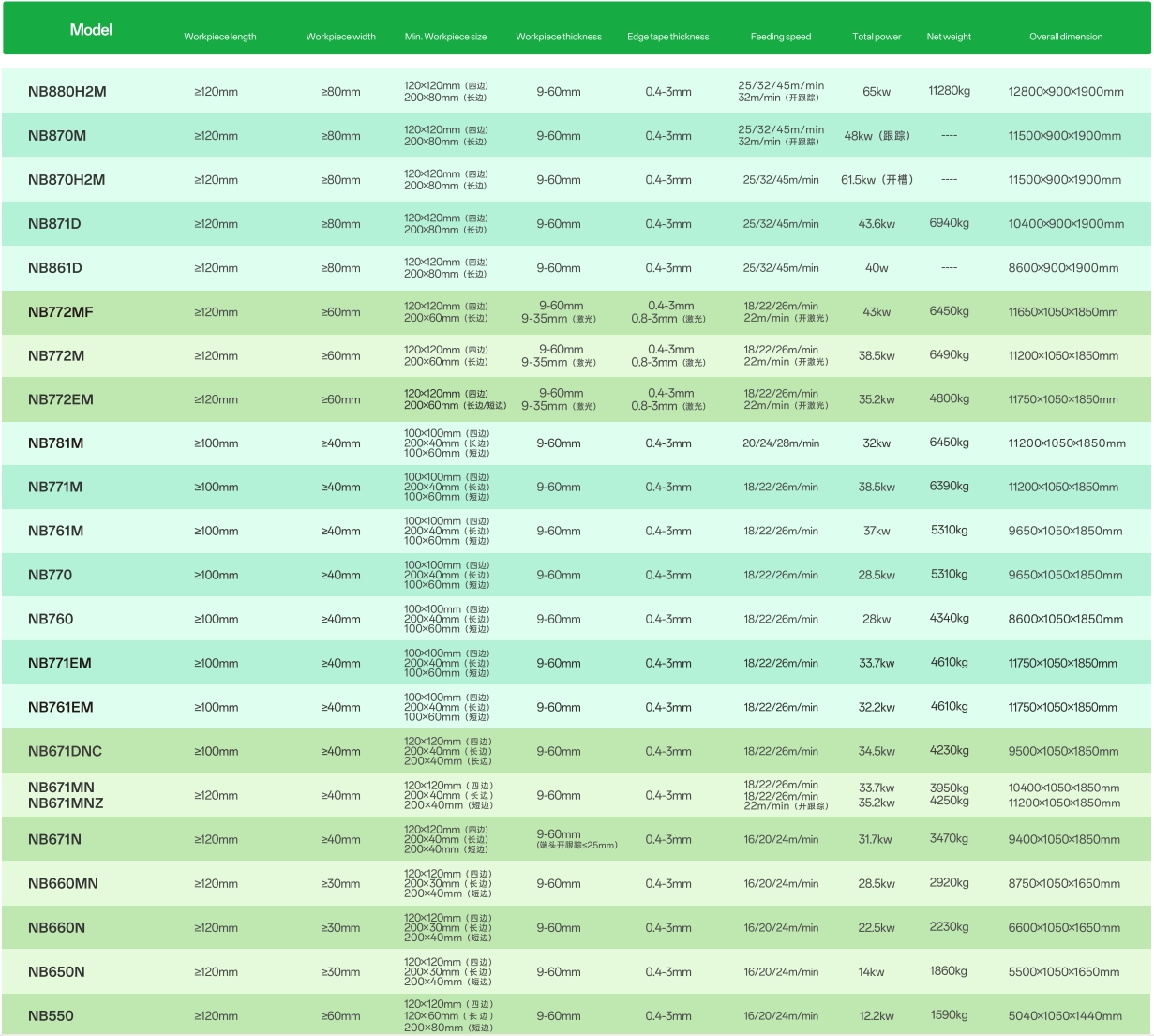

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NB772EM |

| Workpiece Length | ≥120 mm |

| Workpiece Width | ≥60 mm |

| Workpiece Thickness | 9–60 mm |

| Edge Tape Thickness | 0.4–3 mm |

| Min. Workpiece Size | 120×40 mm (with support plate: 200×80 mm) |

| Feeding Speed | 22 m/min |

| Total Power | 35.2 kW |

| Net Weight | 6490 kg |

| Overall Dimension | 11200×1050×1850 mm |

Applications

The NB772EM is ideal for modern panel furniture production lines that require seamless edge aesthetics with high durability. It supports both conventional and laser edge tapes (such as ABS, PVC, PMMA), and is well-suited for kitchen cabinets, office furniture, and high-end interior panels.

NB772M vs NB772EM – Key Differences Overview

| Feature / Component | NB772M | NB772EM |

|---|---|---|

| Edge Bonding Method | Pure laser bonding | Dual bonding system: glue pot + laser generator |

| Glue Pot | Not included | Included – allows use of traditional glue |

| Flexibility of Tape Types | Only supports laser edge tapes | Supports both standard hot-melt and laser tapes |

| Pressing Configuration | Servo pressing before & after laser bonding | Pressing before and after glue pot + laser head |

| Scraping Unit | Double scraping + flat scraping | Double scraping + flexible flat scraping |

| Design Purpose | Optimized for 100% seamless laser processing | Designed for dual-process compatibility |

| Use Case Focus | High-end, fully laser-based edge finishing | Mixed production lines with variable needs |

| Power Consumption | 38.5 kW | 35.2 kW |

| Same Features | Pre-milling, double guide rail, trimming, corner rounding, buffing | Same units, layout adjusted for glue pot addition |

Summary Explanation

-

The NB772M is a dedicated laser edge banding machine, optimized for operations that use laser tape exclusively and demand a fully seamless finish.

-

The NB772EM is a hybrid model, combining both traditional glue and laser bonding methods, offering manufacturers more material compatibility and process flexibility, especially useful when switching between different tape types or product lines.