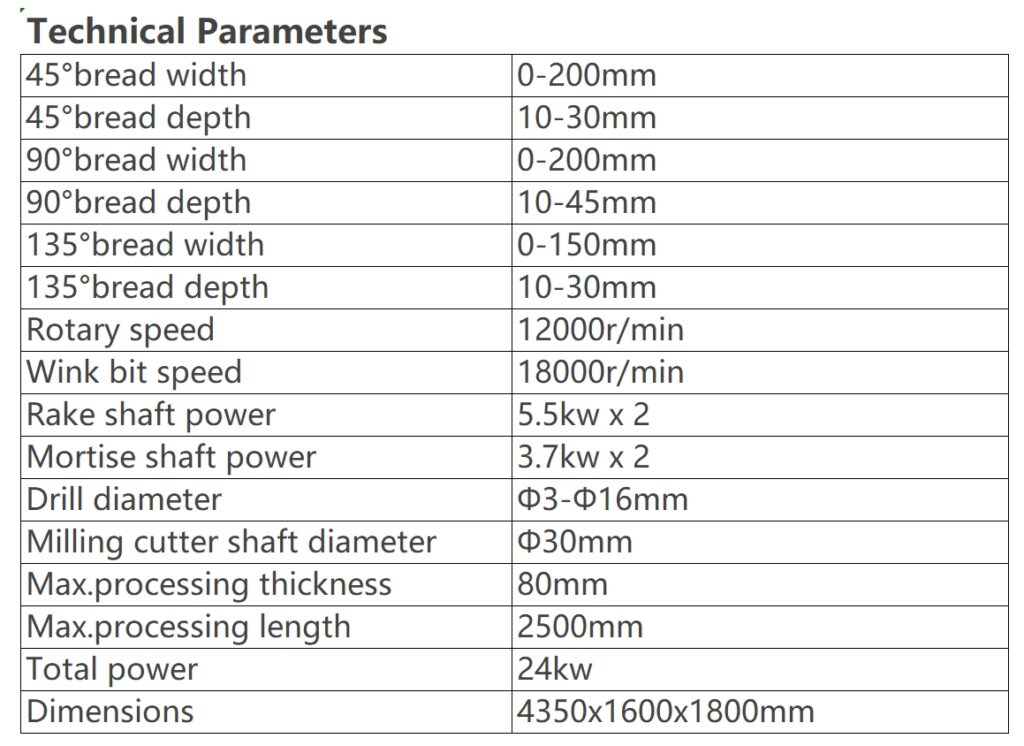

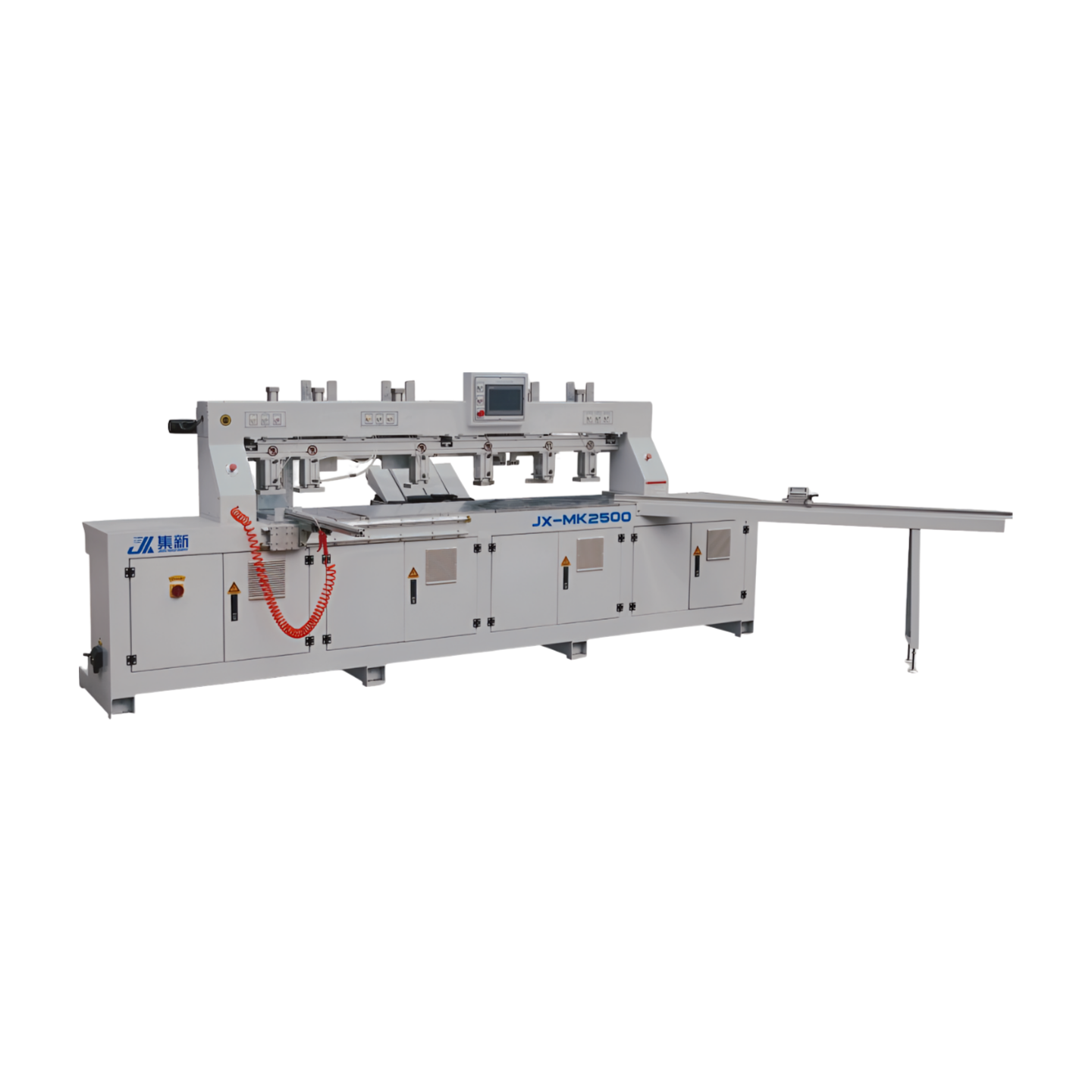

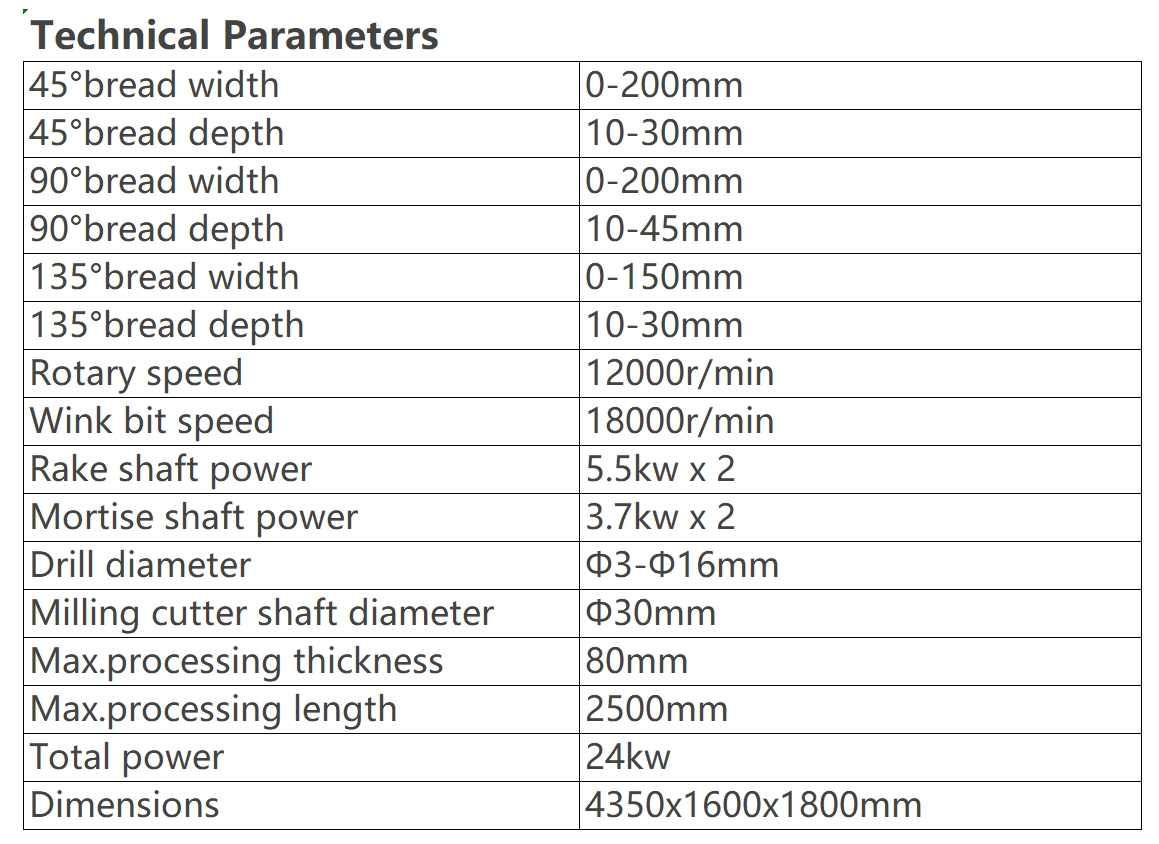

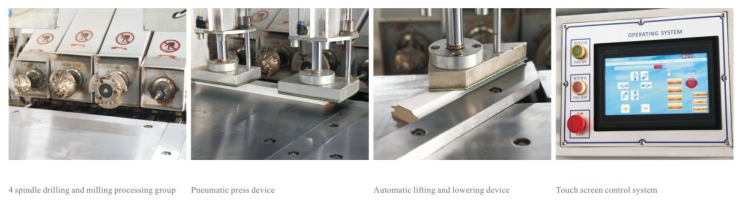

JX-MK2500 CNC Door Frame Processing Center

The JX-MK2500 is a high-efficiency CNC splicing machine designed for precise and multi-angle machining of frame products, assembly doors, and furniture parts made from both solid wood and panel materials. This model integrates cutting, mortising, and milling functions into one advanced processing unit.

Key Advantages

-

Multi-Angle Capability

-

Processes at 45°, 90°, and 135° angles with adjustable width and depth—perfect for frames, corners, and jointed structures.

-

-

High-Speed Dual Spindles

-

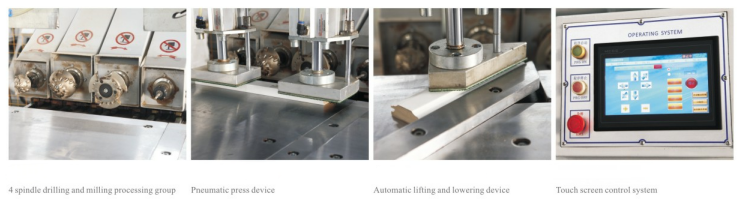

Equipped with rotary speed of 12,000 r/min and wink bit (mortising) speed up to 18,000 r/min, ensuring smooth and accurate cuts even under high throughput.

-

-

Powerful Motor Configuration

-

Dual rake shaft motors at 5.5 kW × 2 and mortising shafts at 3.7 kW × 2, supporting continuous operation with stability and torque.

-

-

Precision Joinery

-

Supports drill diameters from Φ3 to Φ16 mm and milling cutter shafts of Φ30 mm, suitable for both fine and heavy joinery.

-

-

Large Working Capacity

-

Handles workpieces up to 2500 mm in length and 80 mm in thickness, meeting the demands of oversized frame or panel assemblies.

-

-

Compact and Integrated

-

Space-saving design with a footprint of just 4350×1600×1800 mm, perfect for mid-to-large production lines.

-

Recommended For

-

Door frame manufacturers

-

Wooden door & window assembly lines

-

Furniture factories focusing on corner joints and frame assembly

-

Interior solid wood processing shops needing accurate angled mortise & tenon joints