Introduction & Features

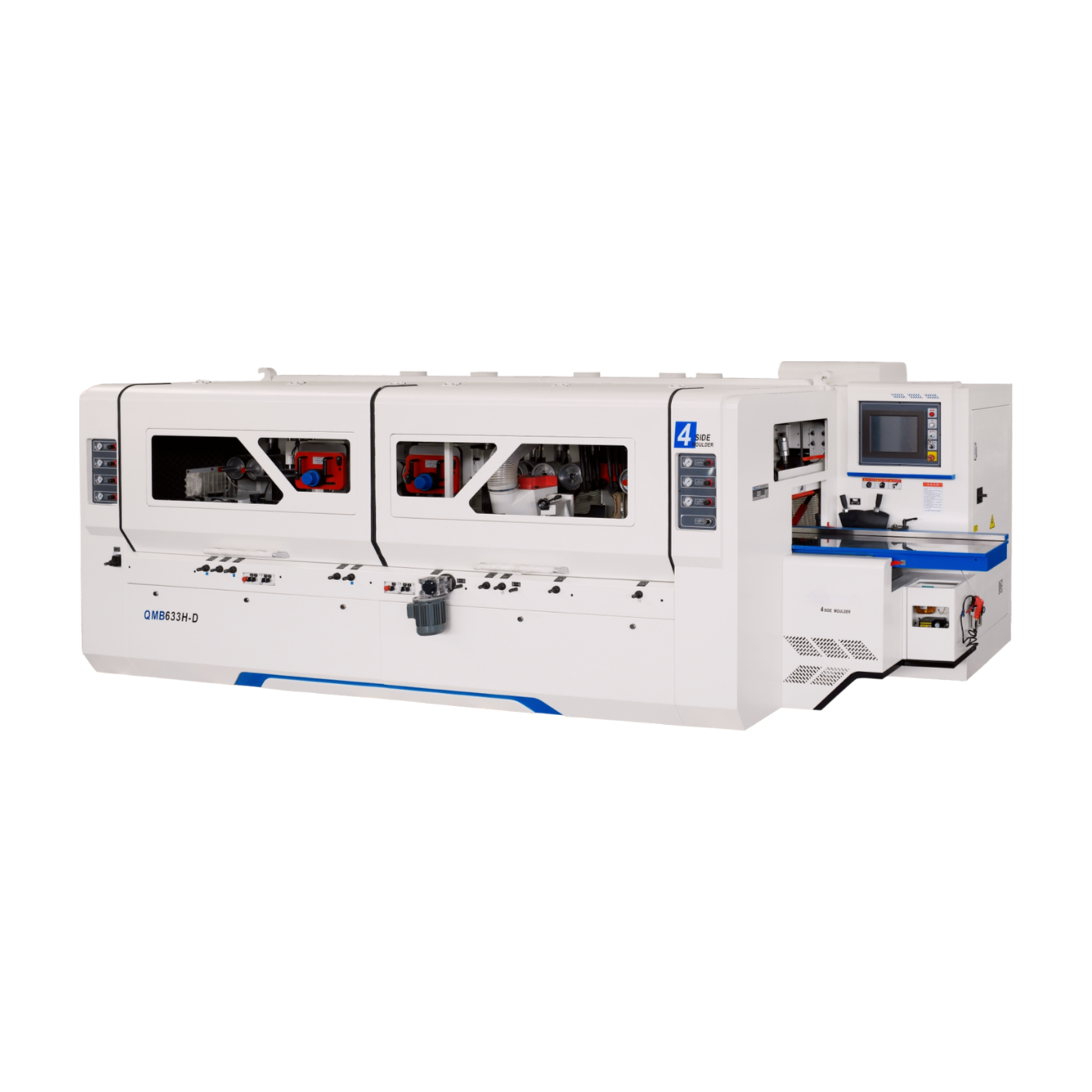

The QMB633H-D Four-Side Planer is an advanced woodworking machine designed for high-precision milling, planing, and shaping of wooden materials. It is particularly suited for large-scale furniture manufacturers, flooring production, and engineered wood processing.

Key Features:

-

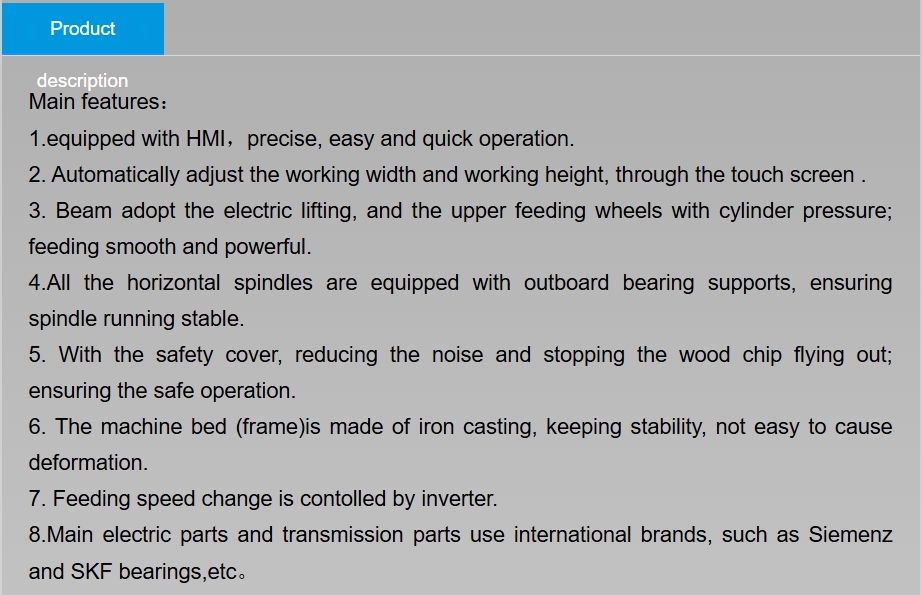

User-Friendly HMI Interface: Ensures precision, ease of operation, and quick setup.

-

Automatic Adjustments: Working width and height can be set via a touch screen.

-

Smooth Feeding System: Features electric beam lifting and cylinder pressure upper feeding wheels to maintain stable and powerful feeding.

-

Stable Spindle Support: Equipped with outboard bearing supports for long-term stability and consistent spindle operation.

-

Enhanced Safety & Noise Reduction: The safety cover reduces noise while preventing wood chips from flying out, ensuring a safe working environment.

-

Durable & Stable Construction: The machine frame is made of iron casting, minimizing deformation and improving long-term reliability.

-

Inverter-Controlled Feeding Speed: Allows smooth speed variations based on processing requirements.

-

International-Grade Components: Uses high-quality transmission parts and electric components from brands like Siemens and SKF bearings for enhanced durability and performance.

Who Should Use This Machine?

-

Furniture Manufacturers: Ideal for producing solid wood furniture and decorative wood components.

-

Wood Flooring Production: Suitable for processing solid wood flooring, engineered boards, and laminated panels.

-

Carpentry & Wood Processing Plants: Efficient for businesses requiring large-scale planing and shaping of wood materials.

This machine is built to deliver high precision, efficiency, and reliability, making it a great investment for woodworking professionals.