Product Details

Related Cases

ML9616SM Four-sided Planer & Rip Saw

High Efficiency | Precision Cutting | Cost-Effective | Material Saving

The ML9616SM is a four-sided planer with left and right vertical axis saw structure, capable of performing sawing operations while maintaining fixed width and thickness. Designed for high-volume production, this machine enhances efficiency, reduces labor costs, and minimizes material waste.

Who is it for?

- Large-scale Wood Processing Plants – Ideal for bulk wood processing with high efficiency and accuracy.

- Furniture Manufacturers – Ensures precise, smooth, and consistent cuts for furniture components.

- Wood Flooring & Panel Producers – Designed for high-speed flooring, decorative boards, and panel cutting.

- Construction & Timber Suppliers – Capable of handling large volumes of wood with optimal material utilization.

Key Advantages

- Heavy-duty Machine Base – Integral casting body with precision processing for extreme stability and durability.

- Abrasion-resistant Worktable – Hard chrome-plated surface, ensuring long-lasting wear resistance.

- High-Precision Cutting System – Dynamically balanced main shaft with imported bearings for accuracy and durability.

- Advanced Feeding Mechanism –

- Universal joint-driven roller feeding for strong and stable material movement.

- 8 upper + 2 lower feeding rollers ensuring continuous processing.

- Active side feed system for improved feeding accuracy and smooth operation.

- Adjustable Speed Control – Variable frequency speed regulation to match different processing requirements.

- Optimized Workpiece Stability – Movable table equipped with a lateral pressure device, preventing drifting and misalignment.

- Labor & Material Cost Reduction – High automation and precision reduce manual adjustments, maximizing efficiency and profitability.

Designed for industries demanding high-speed, precision, and efficiency in wood processing.

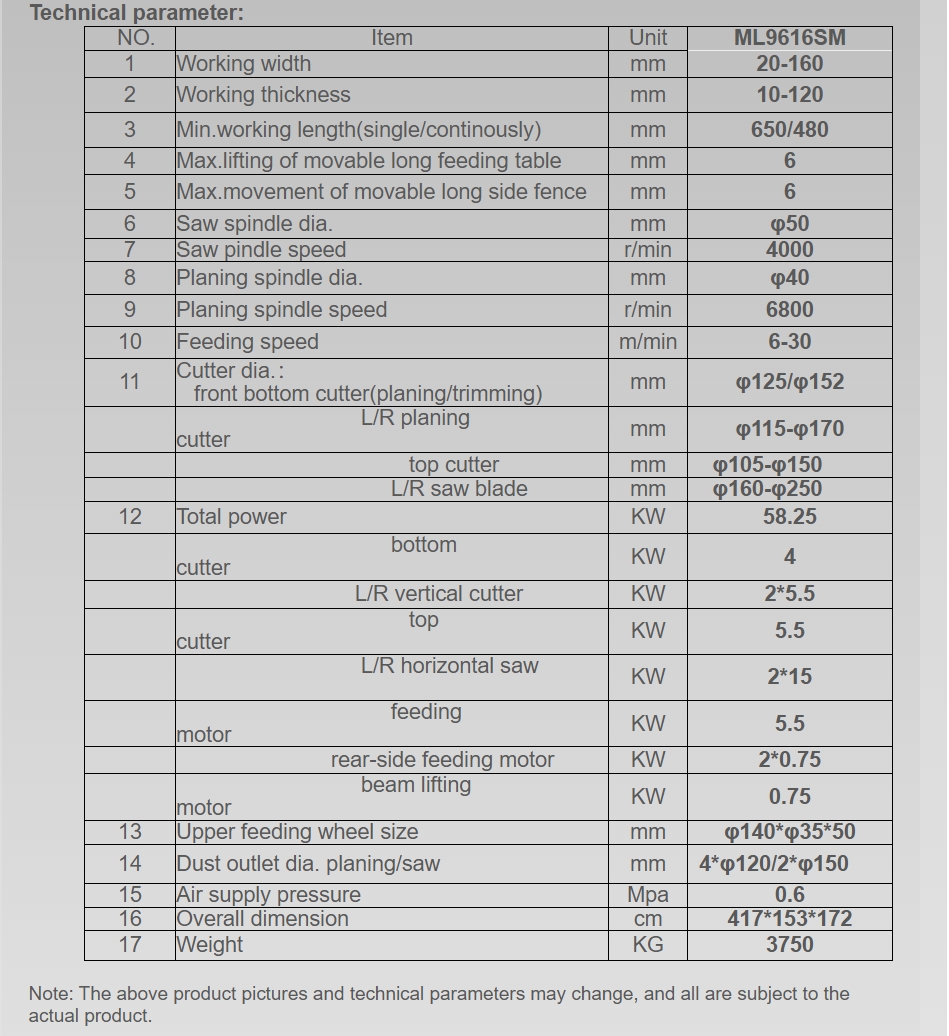

| No. | Item | Unit | ML9616SM |

|---|---|---|---|

| 1 | Working width | mm | 20–160 |

| 2 | Working thickness | mm | 10–120 |

| 3 | Min. working length (single/continuous) | mm | 650 / 480 |

| 4 | Max. lifting of movable long feeding table | mm | 6 |

| 5 | Max. movement of movable long side fence | mm | 6 |

| 6 | Saw spindle diameter | mm | φ50 |

| 7 | Saw spindle speed | r/min | 4000 |

| 8 | Planing spindle diameter | mm | φ40 |

| 9 | Planing spindle speed | r/min | 6800 |

| 10 | Feeding speed | m/min | 6–30 |

| 11 | Cutter diameters (planing/trimming): | ||

| – Front bottom cutter | mm | φ125 / φ152 | |

| – L/R planing cutter | mm | φ115–φ170 | |

| – Top cutter | mm | φ105–φ150 | |

| – L/R saw blade | mm | φ160–φ250 | |

| 12 | Total power | kW | 58.25 |

| – Bottom cutter motor | kW | 4 | |

| – L/R vertical cutter motor | kW | 2 × 5.5 | |

| – Top cutter motor | kW | 5.5 | |

| – L/R horizontal saw motor | kW | 2 × 15 | |

| – Feeding motor | kW | 5.5 | |

| – Rear-side feeding motor | kW | 2 × 0.75 | |

| – Beam lifting motor | kW | 0.75 | |

| 13 | Upper feeding wheel size | mm | φ140 × φ35 × 50 |

| 14 | Dust outlet diameter (planing/saw) | mm | 4 × φ120 / 2 × φ150 |

| 15 | Air supply pressure | MPa | 0.6 |

| 16 | Overall dimensions (L × W × H) | cm | 417 × 153 × 172 |

| 17 | Weight | kg | 3750 |

Time: 20 April, 2025

Project: High-Efficiency Panel Production Line for…

Time: 17 April, 2025

Project: Integrated longitudinal & cross-cut optimization…

No posts found

Related Products

No posts found