Key Advantages of the QMX8025S

-

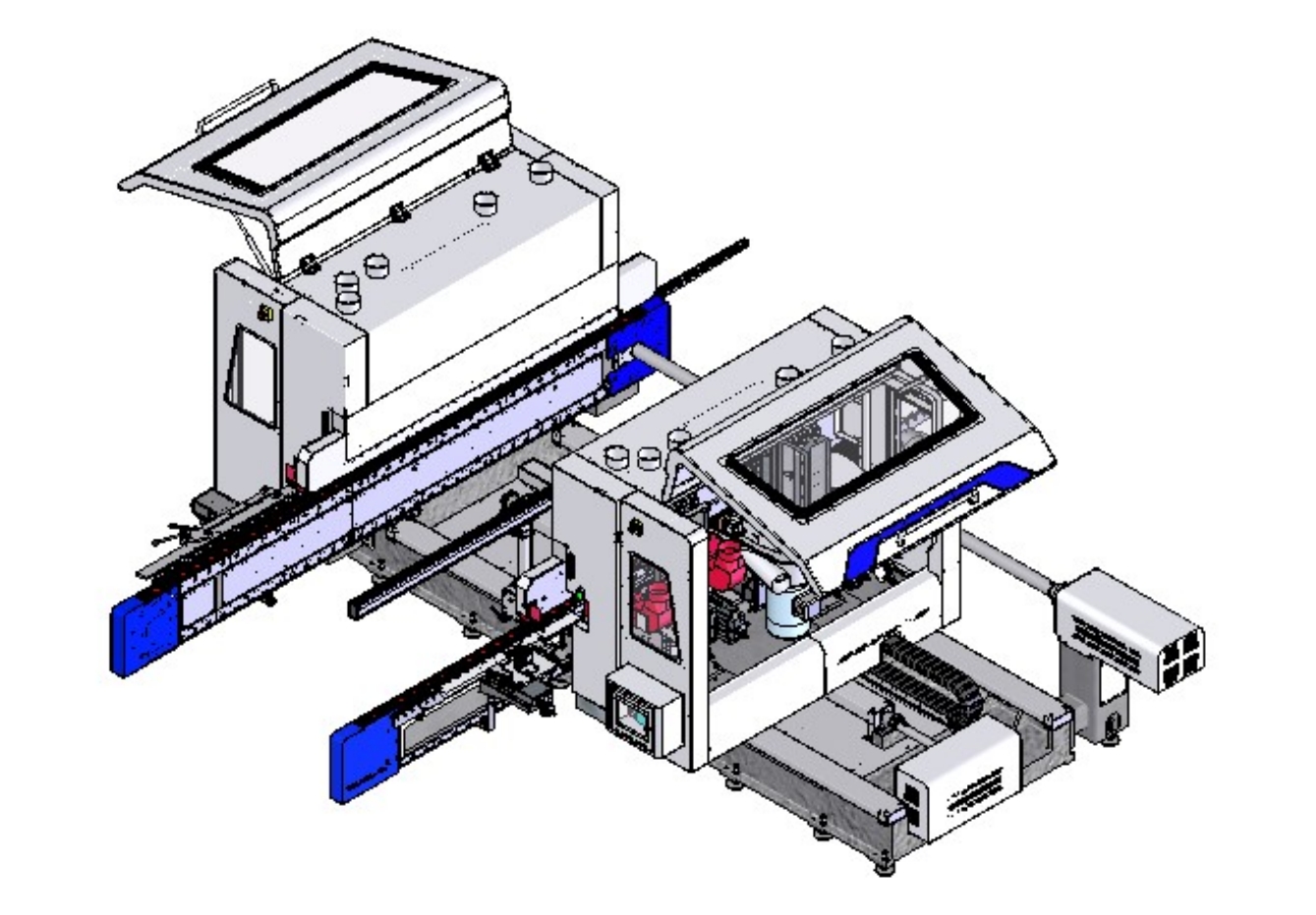

Compact but Powerful

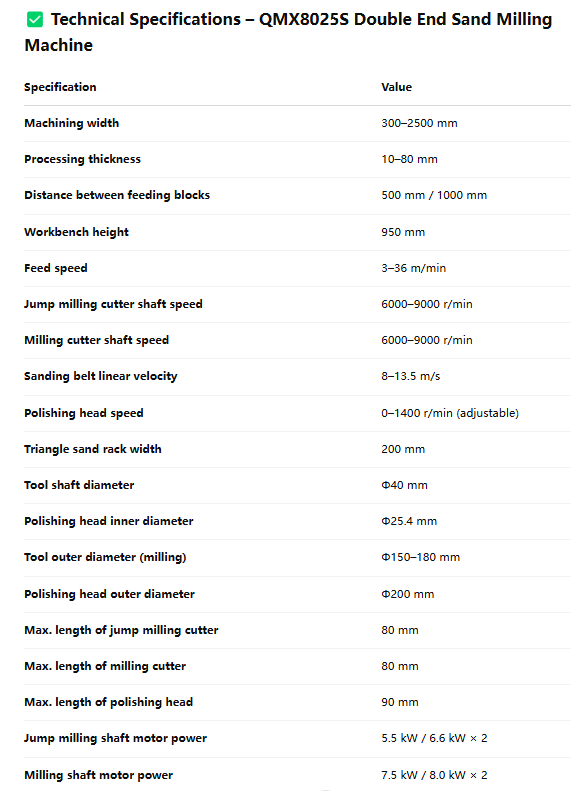

Despite its smaller footprint and lighter weight (7000kg) compared to larger models, the QMX8025S maintains industrial-grade performance. -

High Precision Multi-Process Integration

The machine combines jump milling, continuous milling, and sanding, reducing transfer times and ensuring consistent edge finishing. -

Wide Material Compatibility

Handles a machining width range of 300 to 2500mm, suitable for various wood-based panels, doors, furniture components, and engineered boards. -

Fast and Adjustable Feed Speed

With a feeding speed up to 36 m/min, it supports both high-output production and precision control for delicate workpieces. -

Variable Frequency Polishing Head

Polishing speed up to 1400 r/min with frequency conversion, adaptable to different material textures and finishing requirements. -

Energy-Efficient Motor System

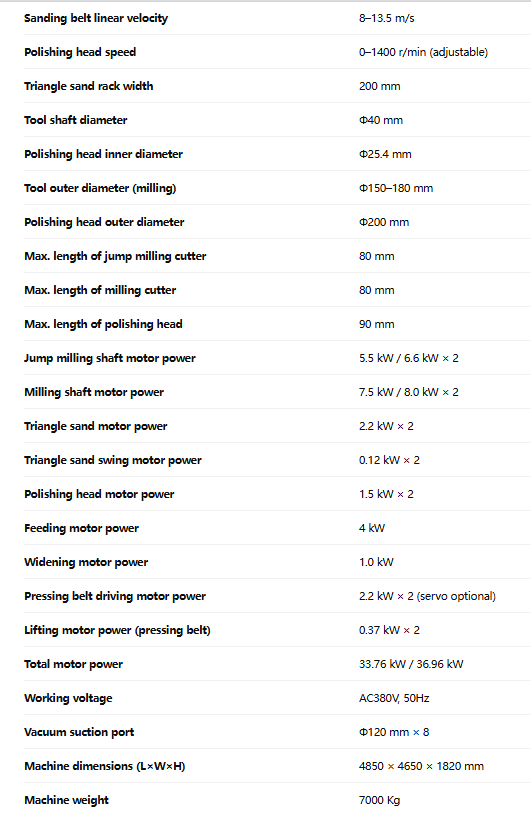

Motor options between 33.76–36.96 kW help users optimize energy consumption based on production needs. -

Excellent Dust Extraction Compatibility

Equipped with 8 large suction ports (Φ120mm) for integration into factory-level vacuum systems, promoting cleaner operation. -

Flexible Customization Options

Offers servo motor selection for pressing belt drive and adjustable spacing (500mm/1000mm between feed blocks), suitable for both standard and special production lines.

Ideal For

-

Panel furniture factories

-

Wooden door manufacturers

-

Decorative board and veneer processors

-

OEM component suppliers in home furnishings