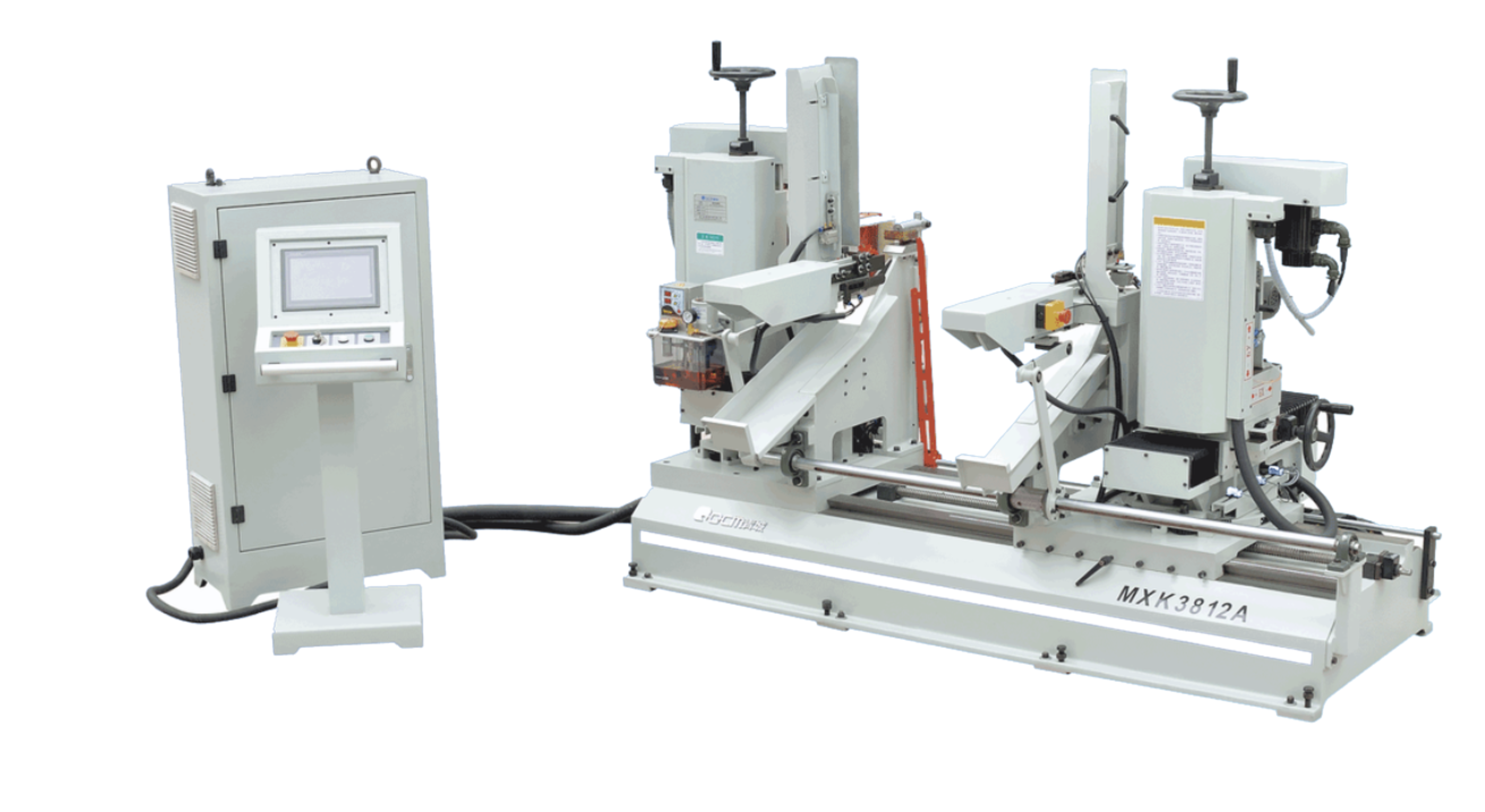

Product Overview

The MXK3812A CNC Automatic Double-End Tenoning Machine is a high-precision woodworking equipment designed for efficient double-end tenoning operations. It integrates CNC control, automatic positioning, and variable-angle cutting functions, making it ideal for producing furniture frames, doors, cabinets, and panel components. The machine performs simultaneous tenoning on both ends of the workpiece, ensuring accuracy, high efficiency, and consistency in batch production.

Key Features

-

CNC control system: Provides intelligent operation and automatic parameter adjustment.

-

Double-end synchronous processing: Ensures precision and high productivity.

-

Adjustable angles: Both horizontal and vertical angles can be adjusted for flexible machining.

-

High-speed spindle: Stable operation with 12,000 rpm cutting speed for smooth surface finish.

-

Durable structure: Heavy-duty cast iron frame ensures vibration resistance and long service life.

-

Wide application: Suitable for solid wood, composite panels, and furniture production lines.

| Parameter | Unit | MXK3812A |

|---|---|---|

| Processing length | mm | 250–1200 |

| Minimum tenon spacing | mm | 200 |

| Processing width | mm | 10–115 |

| Processing thickness | mm | 10–60 |

| Max tenon length | mm | 70 |

| Spindle speed | r/min | 12,000 |

| Spindle diameter | mm | Φ30 |

| Total power | kW | 11.4 |

| Spindle motor power | kW | 3.7 × 2 |

| X-axis motor power | kW | 1.0 × 2 |

| Y-axis motor power | kW | 1.0 × 2 |

| Horizontal angle adjustment | ° | -5° ~ +15° |

| Vertical angle adjustment | ° | -10° ~ +10° |

| Dust outlet diameter | mm | Φ100 × 2 |

| Overall dimensions | cm | 265 × 140 × 170 |

| Machine weight | kg | 1950 |