NB960L Double-Sided Edge Banding Machine

The NB960L is a precision-engineered double-sided edge banding machine designed for medium to large-scale furniture manufacturers. Combining robust structural design with intelligent control, it delivers consistent, high-quality edge finishes on both long sides of the workpiece in a single pass. Ideal for standard panels, cabinets, and custom-sized boards, this model balances speed, efficiency, and precision.

Key Features

-

Simultaneous Dual-Side Banding

Processes both long edges of the panel at once, reducing processing time and improving alignment accuracy. -

Stable Feeding System

Features steel pressure beam with V-belt top press and heavy-duty tank chain with stop cams for secure, vibration-free panel conveyance. -

2-Channel Servo Edge Feeding

Automatically adapts to different tape types and dimensions with precise control. -

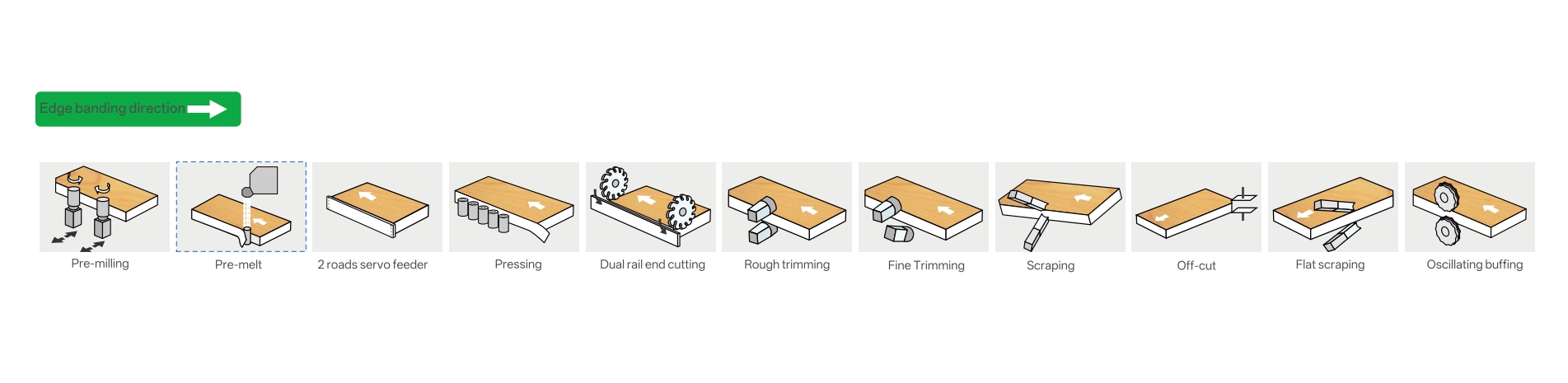

Integrated Processing Units

Includes pre-milling, pre-melting, dual servo feeders, pressing, dual rail end cutting, rough and fine trimming, scraping, off-cut handling, flat scraping, and oscillating buffing. -

Synchronization Technology

Synchronization between the pressure beam and belt ensures smooth and accurate edge application, especially for longer panels. -

Compact & Efficient Layout

Compact frame for factory line integration while maintaining all critical edge banding pro

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NB960L |

| Max. Workpiece Size | 2500 mm |

| Min. Workpiece Size | 285 mm |

| Workpiece Thickness | 9–60 mm |

| Edge Tape Thickness | 0.4–3 mm |

| Feeding Speed | 20 / 22 / 24 m/min |

| Total Power | 55 kW |

| Net Weight | 11550 kg |

| Overall Dimension | 9500×4400×1950 mm |

Applications

Suitable for edge banding of cabinet panels, shelves, drawer components, and architectural woodwork in batch production lines. The NB960L is widely adopted in medium and large furniture production facilities seeking an efficient and cost-effective double-sided banding solution.