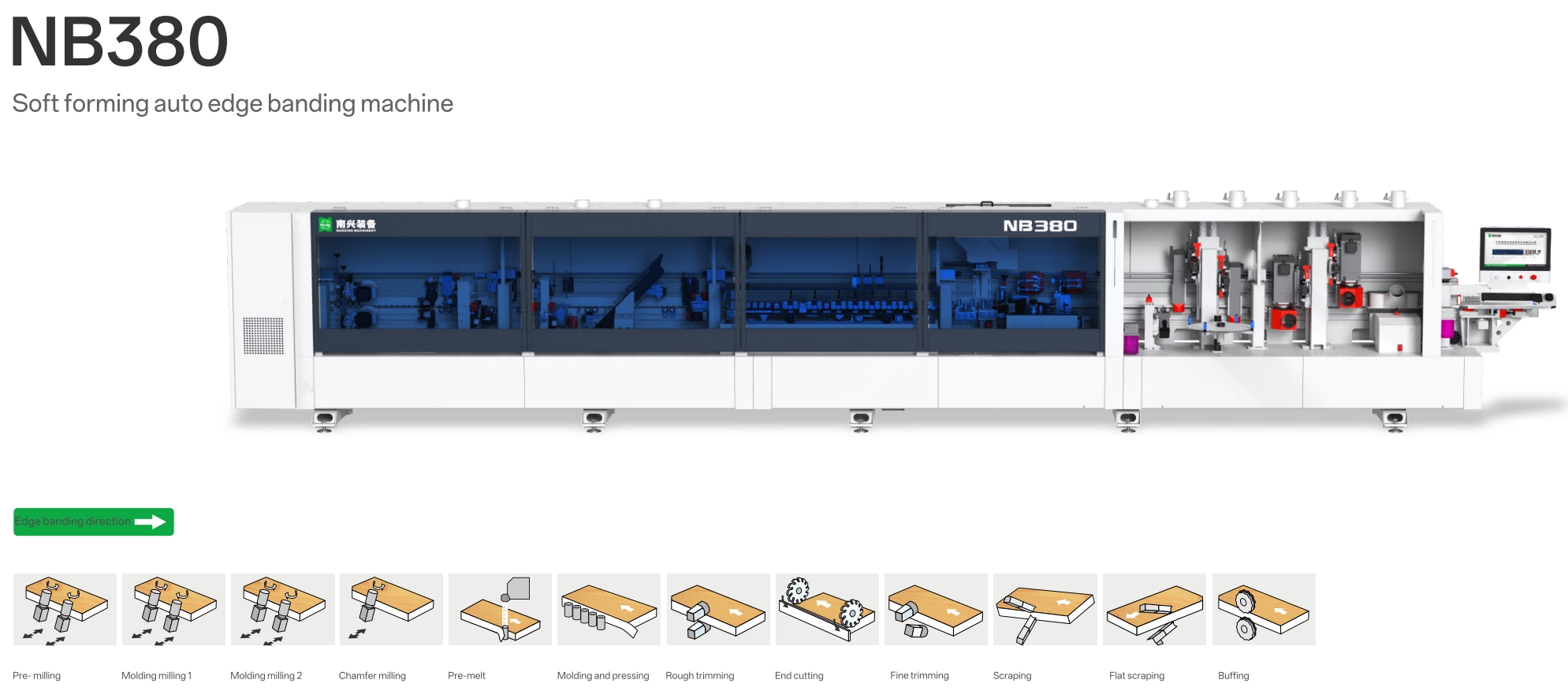

NB380 Soft Forming Auto Edge Banding Machine

The NB380 is a fully automated soft forming edge banding solution tailored for producing complex door panel profiles. Featuring advanced contour milling and pressing technology, it enables seamless edge finishing on irregular or molded profiles, delivering elegant aesthetics and precise craftsmanship for high-end panel furniture and decorative door applications.

Key Features

-

Specialized for Soft Forming Edges

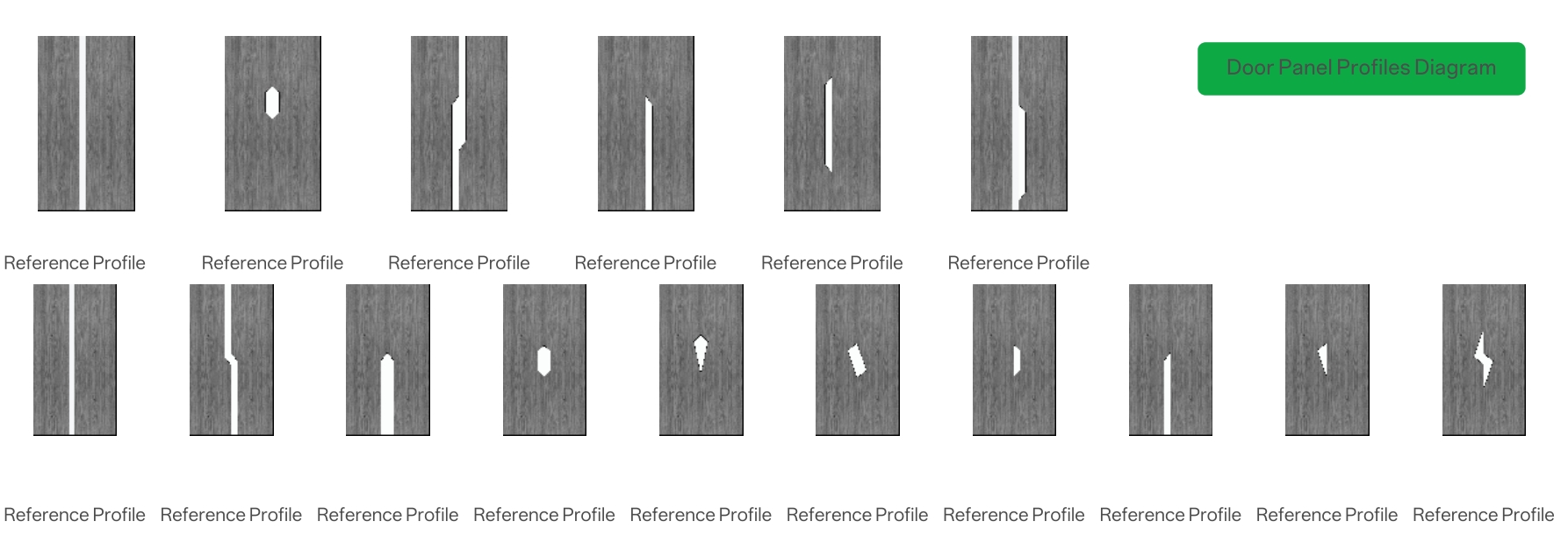

Supports a wide range of 3D door panel profiles through multiple shaping and molding milling units. -

Multi-Axis Contour Processing

Equipped with dual molding milling units and a chamfer milling station for precision shape preparation prior to banding. -

Integrated Molding & Pressing System

Automatically adapts to curved surfaces for tight bonding between panel and edge tape. -

Full Edge Banding Workflow

Includes pre-milling, pre-melt, rough and fine trimming, end cutting, dual scraping, flat scraping, and buffing for a complete finish. -

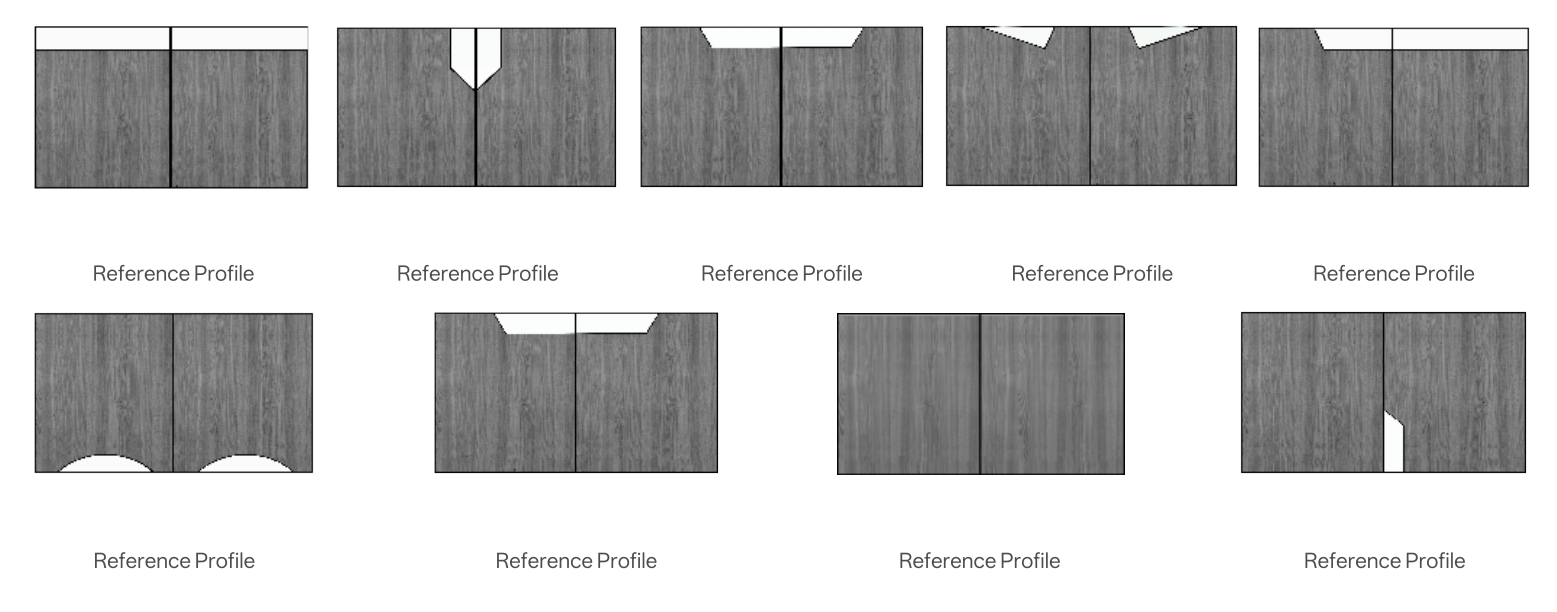

Large Format Panel Compatibility

Suitable for larger door sizes with complex edge patterns and custom contours. -

Profile Versatility

Capable of processing dozens of reference profile types as shown in the door panel diagram, including straight-line, V-groove, diamond-cut, and wave contours.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NB380 |

| Min. Workpiece Size | 300×150 mm |

| Workpiece Thickness | 18 mm |

| Edge Tape Thickness | 0.5–0.6 mm |

| Feeding Speed | 8 m/min |

| Total Power | 68 kW |

| Net Weight | 5900 kg |

Applications

The NB380 is ideal for high-end door production, including kitchen cabinet doors, wardrobe panels, and other molded panel furniture. It excels in delivering smooth and uniform edge finishes on shaped profiles that require both functional strength and visual appeal.