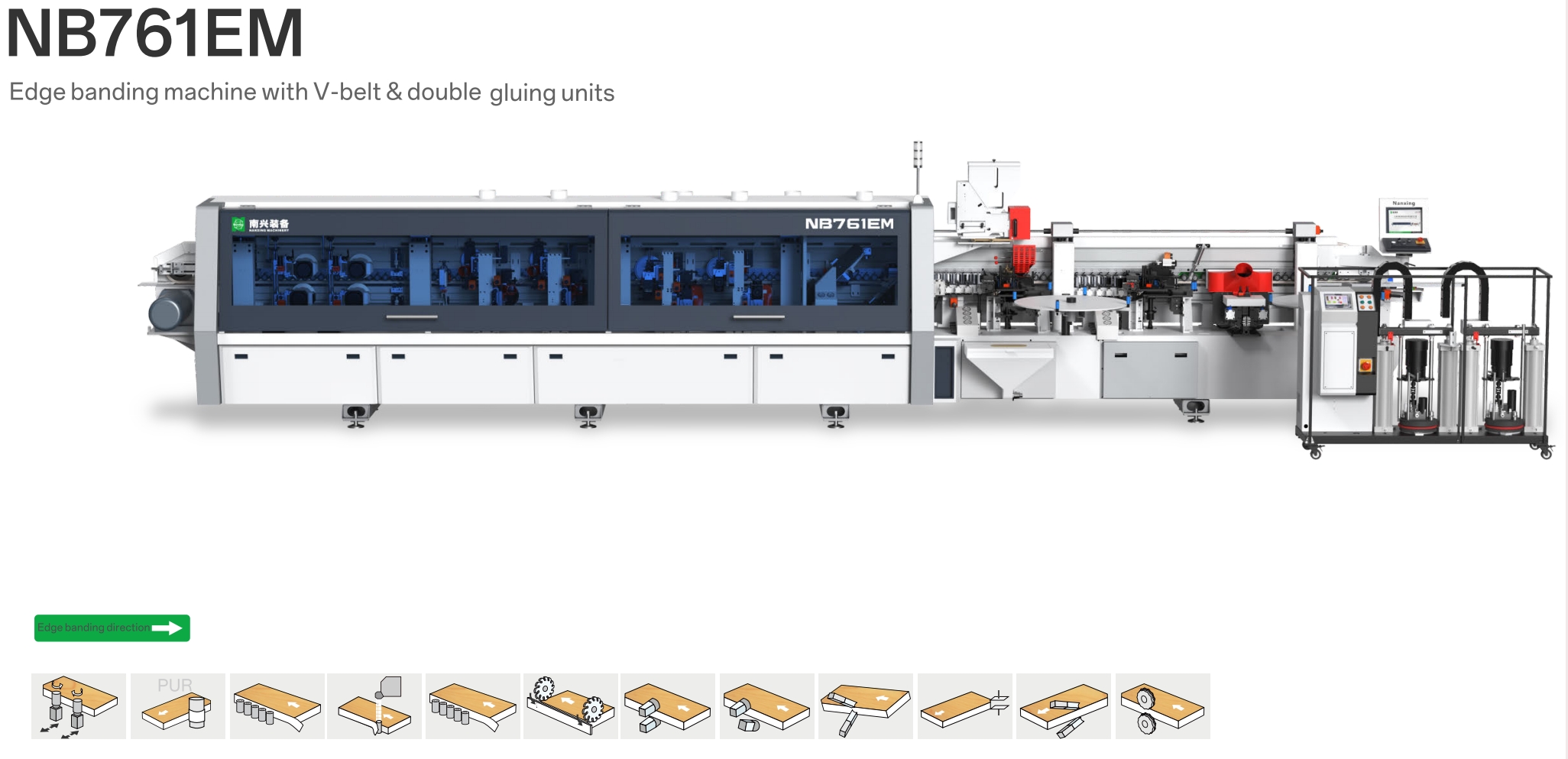

NB761EM Edge Banding Machine with V-Belt and Double Gluing Units

The NB761EM is a compact yet powerful edge banding machine equipped with dual PUR gluing units and a modular high-speed processing system. Designed for flexibility and production continuity, it is well-suited for small to mid-sized panel manufacturers who need professional-grade edge quality and material adaptability.

Key Features

-

Dual PUR Glue System with Pre-Melting

Features a two-color, no-cleaning PUR glue pot with independent pre-melt station, supporting high-gloss surfaces and complex applications without downtime. -

Steel Pressure Beam with V-Belt Top Presser

Ensures stable feeding pressure and precise workpiece alignment during high-speed operation. -

Dual Rail End Cutting + Horizontal Scraping Units

Accurate end trimming and horizontal scraping deliver clean transitions and a premium-quality edge finish. -

Streamlined Process Layout

Includes pre-milling, PUR gluing, dual pressing, dual rail end cutting, rough & fine trimming, high-speed corner rounding, double scraping, flexible flat scraping, off-cut, and double oscillating buffing – all integrated into one machine. -

User-Friendly Automation & Safety Monitoring

Equipped with intelligent PC control, visual interface, glue tank status alerts, and real-time temperature/pressure monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | NB761EM |

| Workpiece Length | ≥100 mm |

| Workpiece Width | ≥40 mm |

| Workpiece Thickness | 9–60 mm |

| Edge Tape Thickness | 0.4–3 mm |

| Min. Workpiece Size | 100×40 mm (with support plate: 200×80 mm) |

| Feeding Speed | 18/22/26 m/min |

| Total Power | 32.2 kW |

| Net Weight | 4610 kg |

| Overall Dimension | 11750×1050×1850 mm |

Applications

NB761EM is tailored for manufacturers of modular furniture, kitchen cabinets, and interior panel systems. It is especially beneficial for production environments that require fast glue color switching, PUR application, and consistent finishing quality without increasing machine footprint or complexity.