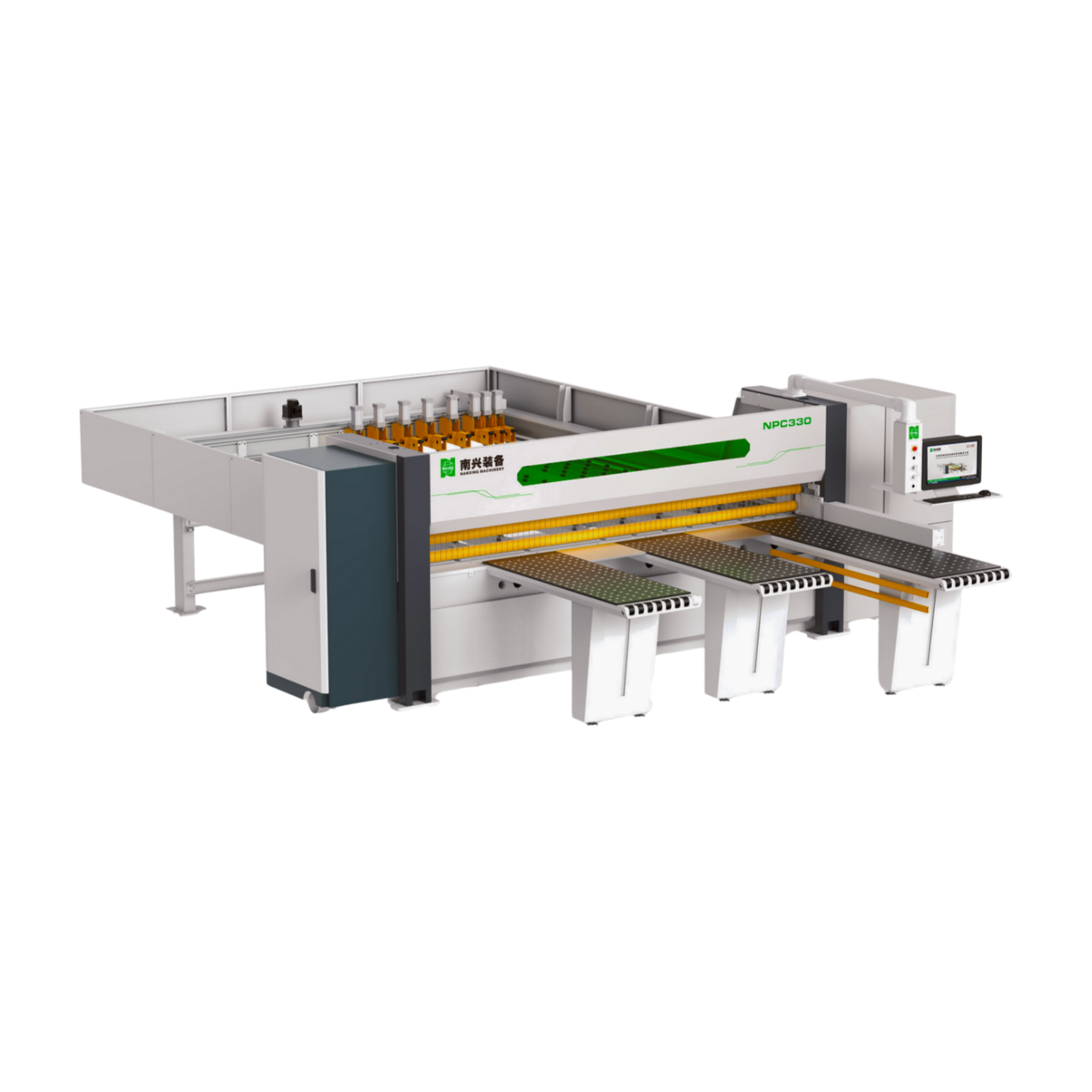

NPC330 High-Speed Computer Panel Saw

Precision, Stability, and Efficiency for Modern Wood Panel Cutting

The NPC330 High-Speed Computer Panel Saw is a next-generation industrial cutting solution engineered for precise, high-volume wood panel processing. Built with a heavy-duty steel frame and optimized for intelligent automation, this machine is ideal for manufacturers aiming to boost productivity and maximize material utilization.

Technical Features

| Parameter | Specification |

|---|---|

| Max. Processing Length | 3270 mm |

| Max. Processing Height | 90 / 120 mm (optional) |

| Saw Carriage Speed | 90 m/min (forward) / 120 m/min (backward) |

| Feeding Speed | 85 m/min (automatic feeding) |

| Main Saw Motor Power | 15 kW (optional 18.5 kW) |

| Scoring Saw Motor Power | 2.2 kW |

| Gripper Quantity | 10 units |

| Total Installed Power | 24.2 kW |

| Net Weight | 4800 kg |

| Overall Dimensions | 6900 × 5400 × 1820 mm |

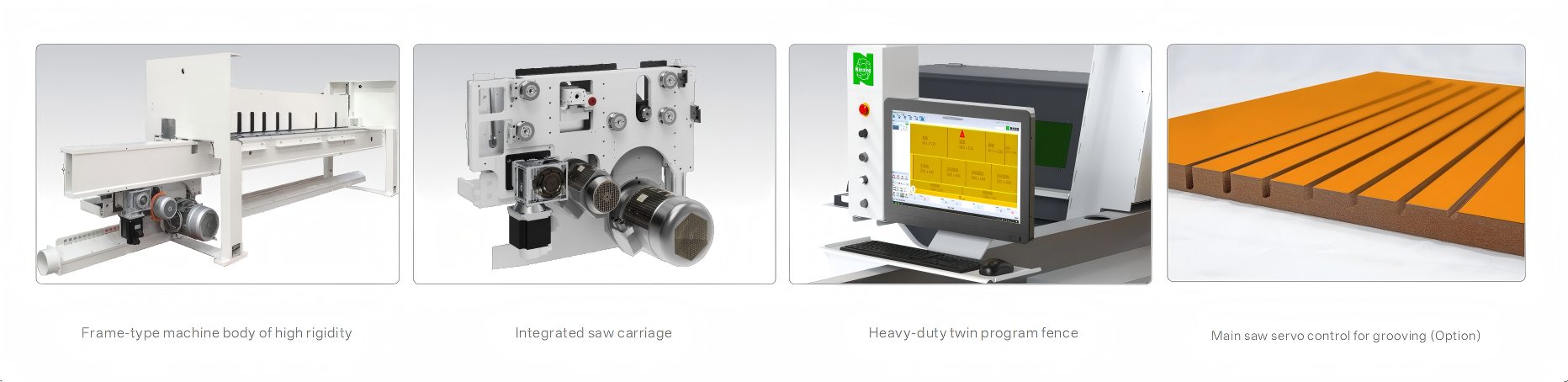

Structural Advantages:

-

Frame-Type Machine Body: Constructed for rigidity and long-term structural stability, ensuring accurate cutting under continuous heavy-duty cycles.

-

Integrated Saw Carriage: High-precision aluminum carriage offers reduced vibration and smoother operation.

-

Smart Control System: Equipped with dual-program fence automation, allowing for efficient panel layout optimization and rapid changeovers.

-

Servo-Controlled Grooving Function (Optional): The main saw can be servo-lifted to achieve continuous groove cutting—perfect for custom panel applications.

Application Advantages:

-

Supports efficient and accurate cutting of plywood, particle board, MDF, and other engineered panels.

-

Fully automated operation with real-time optimization software reduces material waste and labor costs.

-

Ideal for furniture manufacturers, cabinetry producers, and panel processing plants looking for smart factory upgrades.