QMJ6425E Double-End Cutting and Grooving Machine

Product Overview:

The QMJ6425E is a double-end cutting and grooving machine designed for high-efficiency panel processing in woodworking industries. It features stable feeding, precise cutting, and powerful dual saw systems—making it ideal for solid wood furniture, flooring, and door panel production.

Key Features:

-

Working Range: Supports a max working width of 2500mm and a thickness range of 10–60mm, suitable for various board sizes.

-

Dual-Saw System: Equipped with both top and bottom spindles operating at 3000 rpm, reducing edge chipping and improving cut quality.

-

Precision Control: Positioning blocks are spaced at 400mm, enabling accurate alignment and feed speed up to 24 m/min.

-

Sturdy Construction: Heavy-duty frame with 900mm worktable height ensures long-term durability and operator comfort.

-

Power System: Total power of 15.35kW, with each scoring saw at 2.2kW and each cutoff saw at 4.0kW.

-

Dust Management: Dual 120mm outlets for efficient chip and dust extraction.

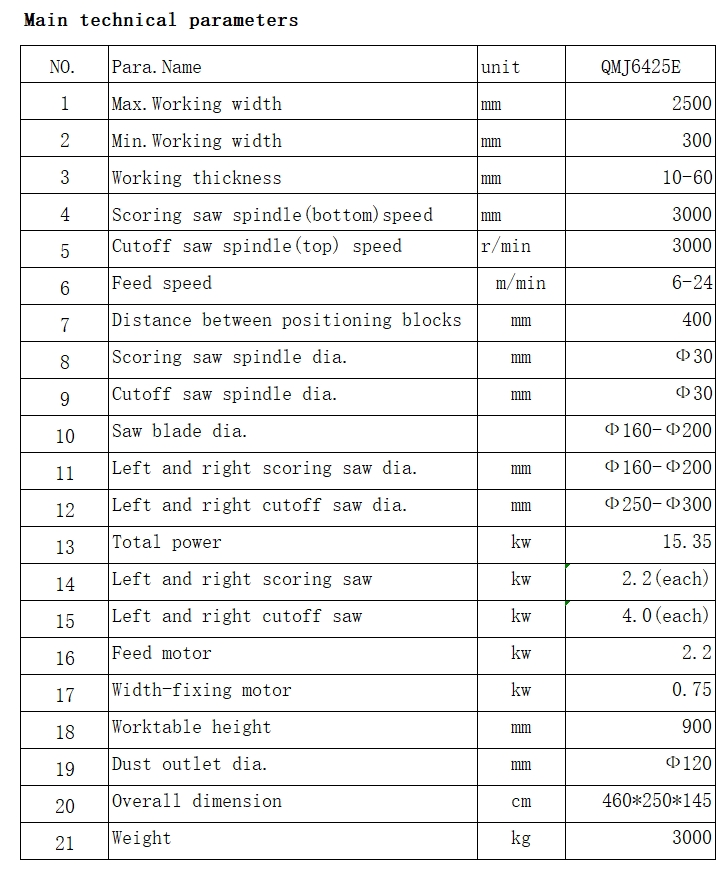

Technical Specifications

| Specification | Value |

|---|---|

| Max. Working Width | 2500 mm |

| Min. Working Width | 300 mm |

| Working Thickness | 10–60 mm |

| Spindle Speed (Top & Bottom) | 3000 r/min |

| Feed Speed | 6–24 m/min |

| Saw Blade Diameter | Φ160–Φ200 mm |

| Cutoff Saw Diameter | Φ250–Φ300 mm |

| Total Power | 15.35 kW |

| Feed Motor | 2.2 kW |

| Width-Fixing Motor | 0.75 kW |

| Worktable Height | 900 mm |

| Overall Dimension (L×W×H) | 460×250×145 cm |

| Weight | 3000 kg |

Applications:

Perfect for woodworking plants producing door panels, floorboards, cabinet parts, and other straight-edge panel products that require high accuracy and speed.

Who is it for?

-

Furniture Manufacturers – Ensures precise edge trimming and accurate panel sizing, reducing waste.

-

Wood Panel & Flooring Factories – Delivers clean and smooth cuts for wood boards, laminated panels, and flooring materials.

-

Construction Material Suppliers – Ideal for processing large wood boards, beams, and construction panels.

-

Timber Processing Plants – Perfect for bulk production with consistent cutting quality.

Key Advantages

-

“Double-end Cutting System” – Cuts both panel edges simultaneously, improving efficiency and productivity.

-

“Scoring + Cutoff Saws” – Prevents chipping and splintering, ensuring a smooth and professional finish.

-

“Adjustable Feed Speed (6~24m/min)” – Adaptable to different wood types and thicknesses, optimizing workflow.

-

“High Power & Stability” – 15.35kW total power, delivering strong cutting performance and long-term reliability.

-

“Heavy-duty Structure” – Robust machine frame for stable operation and vibration-free cutting.

-

“Advanced Dust Collection System” – φ120mm dust outlet ensures a clean and safe working environment.