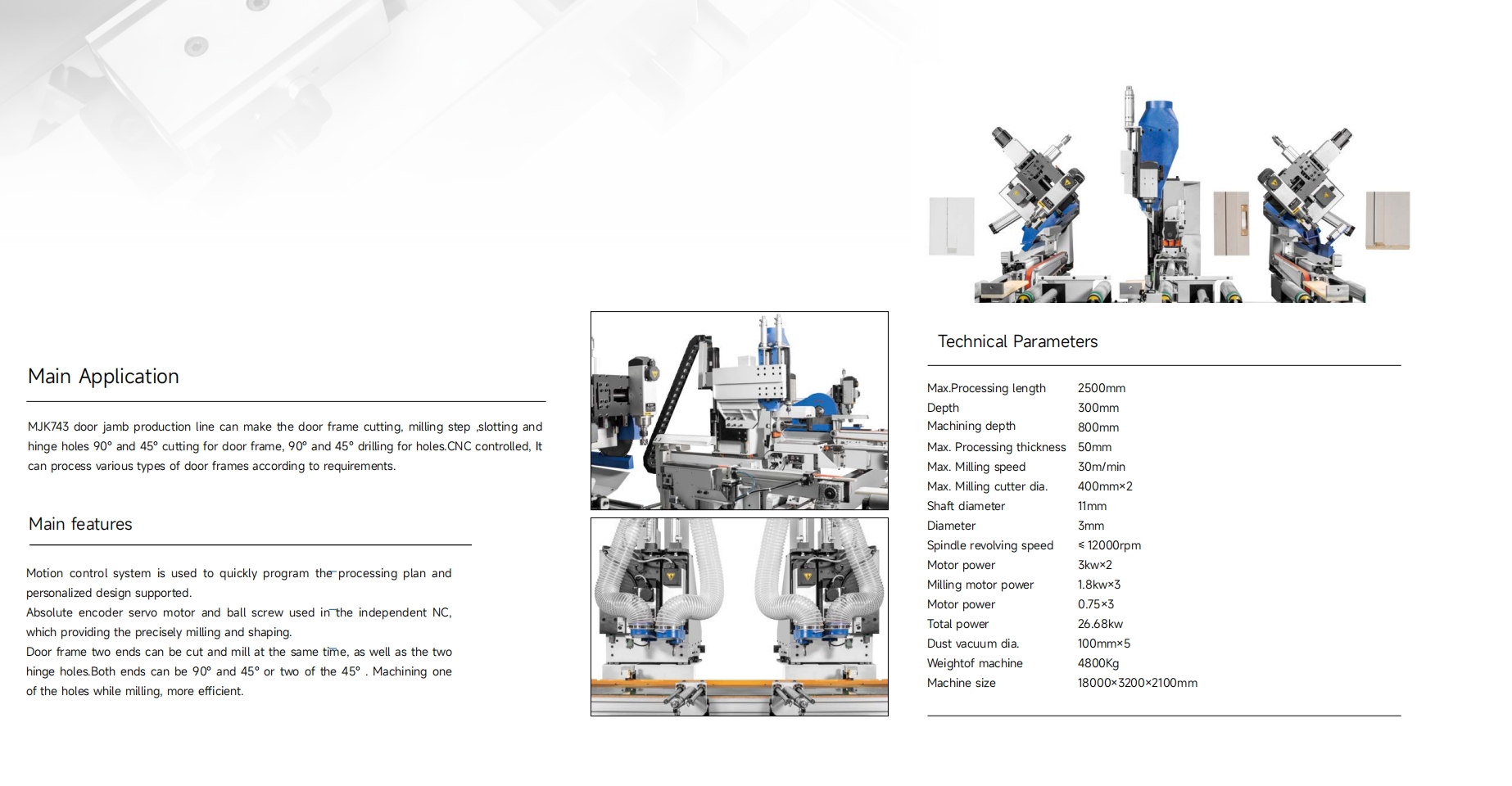

MJK743 Door Frame Processing Line

Application Overview

The MJK743 is a CNC-controlled door jamb production line designed for precision milling and drilling. It enables 90° and 45° cutting for door frames and hinge holes, supporting multi-angle processing requirements. Ideal for high-efficiency door frame manufacturing with automated programming and servo control.

Key Features

-

Simultaneous Dual-End Processing: Allows both ends of the frame to be milled and drilled at 90° and 45°, or two of the 45° angles simultaneously.

-

High-Precision Control: Utilizes encoder servo motors and ball screw systems for accurate shaping and positioning.

-

Flexible Programming: Built-in motion control system enables easy configuration of custom machining plans.

-

Full Automation: Supports integration into larger automated production lines.

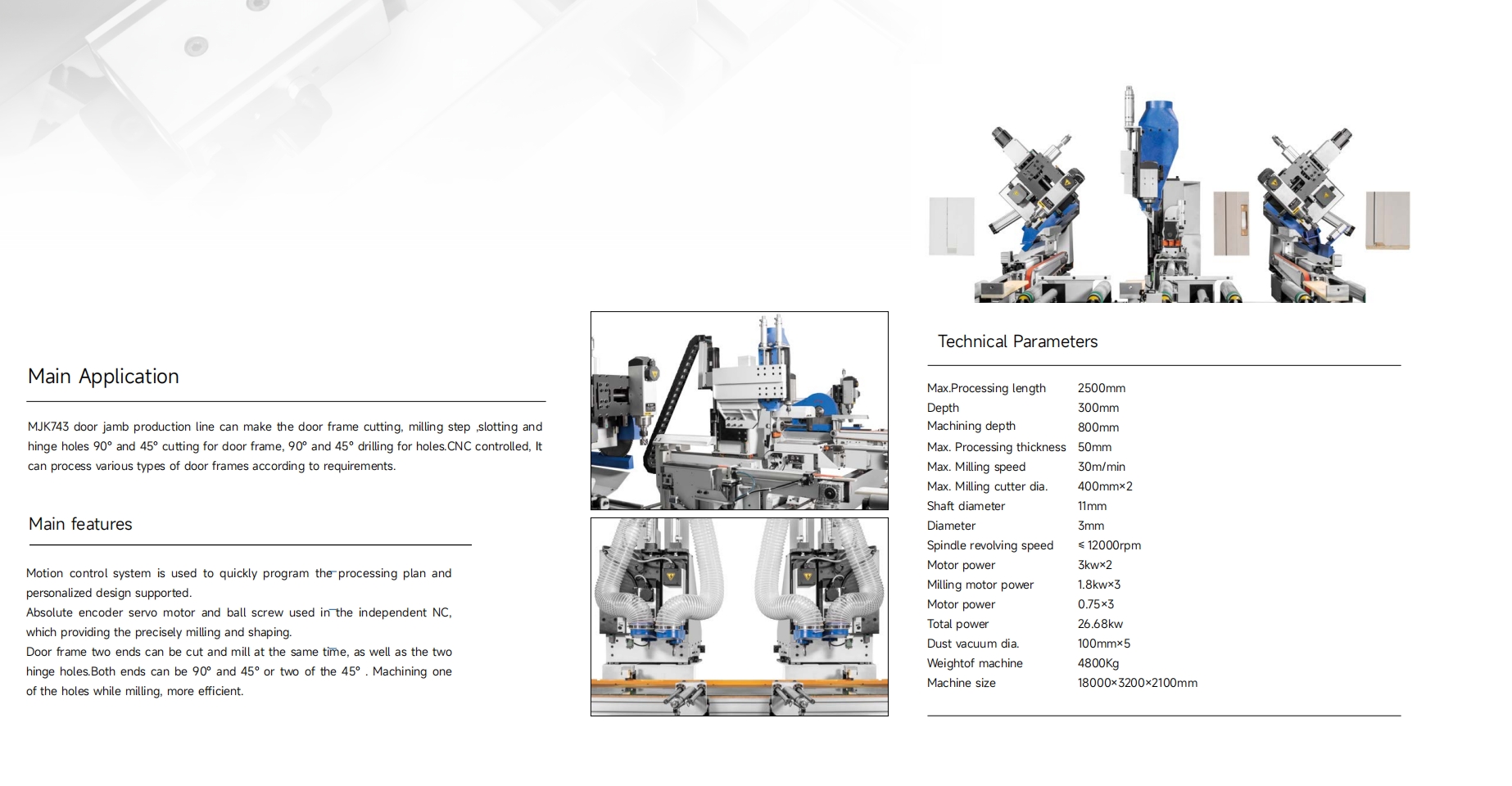

Technical Specifications

-

Max. Processing Length: 2500 mm

-

Processing Thickness: Up to 50 mm

-

Max. Milling Speed: 30 m/min

-

Tool Diameter: 400 mm × 2

-

Spindle Speed: ≤ 12,000 rpm

-

Total Power: 26.8 kW

-

Vacuum Ports: 5 × Ø100 mm

-

Machine Weight: 4800 kg

-

Dimensions: 18000 × 3200 × 2100 mm

Who Uses This Machine?

-

Door manufacturers specializing in custom frame designs

-

Industrial furniture workshops focused on batch production

-

Companies aiming to build automated woodworking production lines

-

Businesses seeking high throughput and consistent cutting quality

设备效果图.png)