Advantages of QMX1206DT

-

High Precision

-

Uses a high-precision conveyor chain for accurate machining.

-

-

Fast Processing Speed

-

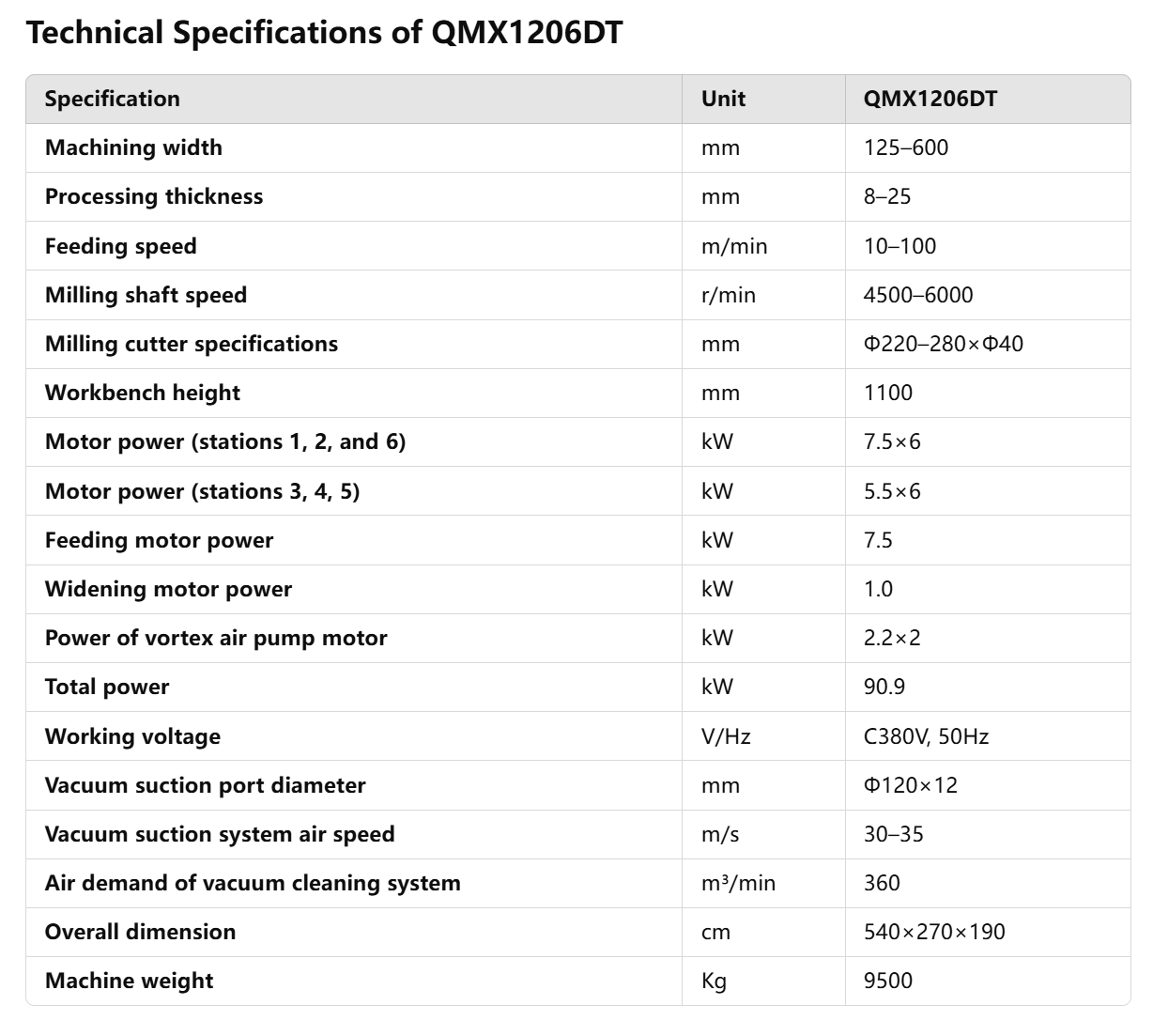

The machine operates at high speeds with an adjustable feeding speed of 10–100 m/min, ensuring efficiency.

-

-

Versatile Processing Capabilities

-

Supports a variety of board sizes and thicknesses, making it adaptable for different wood processing needs.

-

-

Customizable Configurations

-

Blade axis configurations can be customized, including 8-axis, 10-axis, and 12-axis setups.

-

-

Double-End Tenoning Operation

-

Efficiently performs male tenoning on both ends of materials, supporting slotted wood processing.

-

-

Industrial-Level Durability

-

High power output of 90.9 kW and a strong vacuum suction system ensure consistent performance.

-

-

Seamless Integration with Assembly Lines

-

Designed for automated production lines, making it ideal for mass production environments.

-

Who Would Use This Machine?

-

Furniture Manufacturers

-

Ideal for companies producing furniture with wooden joints and lock mechanisms like ThreeSpine buckle types.

-

-

Wood Flooring Producers

-

Suitable for solid wood flooring and engineered veneer boards, where precise tenoning is required.

-

-

Door and Window Frame Manufacturers

-

Useful for manufacturing wooden door frames, window frames, and other decorative wooden components.

-

-

Panel and Board Factories

-

Perfect for particleboard and veneer processing plants.

-

-

Large-Scale Wood Processing Plants

-

Companies involved in mass production of wood-based products that require high-speed and high-precision machining.

-