JX-ST1200 Mortise Processing Center

The JX-ST1200 Mortise Processing Center is a high-precision woodworking CNC machine specifically developed for efficient mortise slotting operations in furniture and solid wood components.

Key Advantages

-

High-Speed & Precision Performance

-

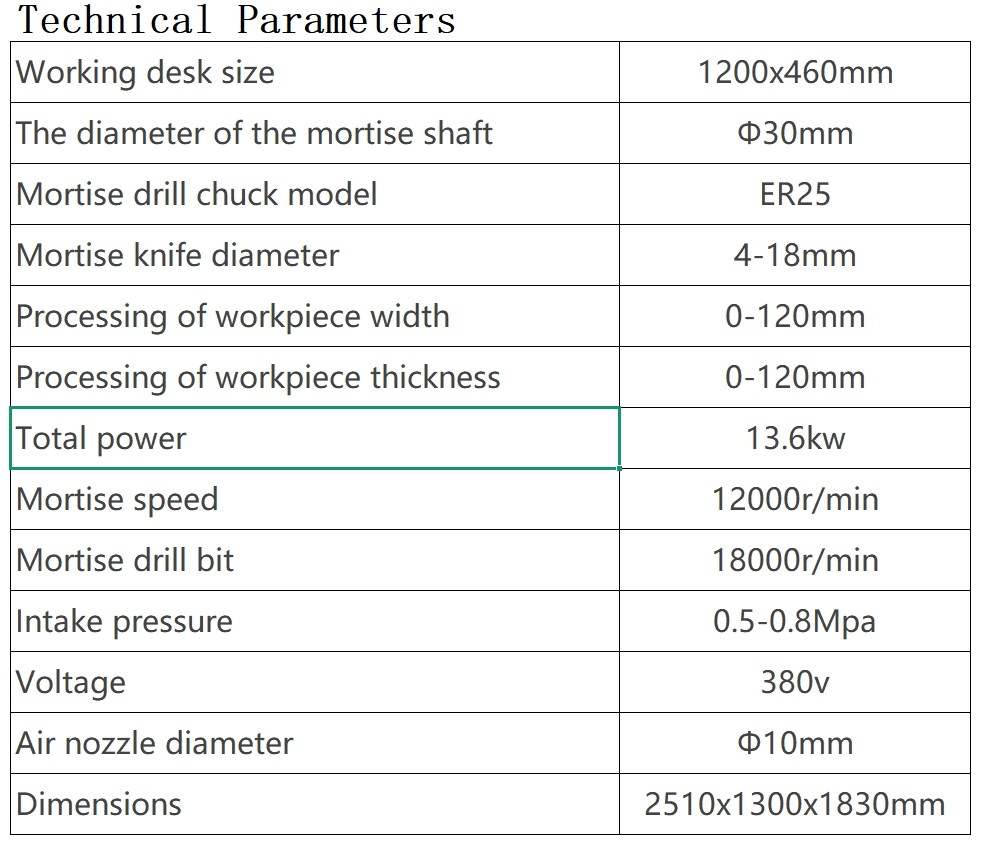

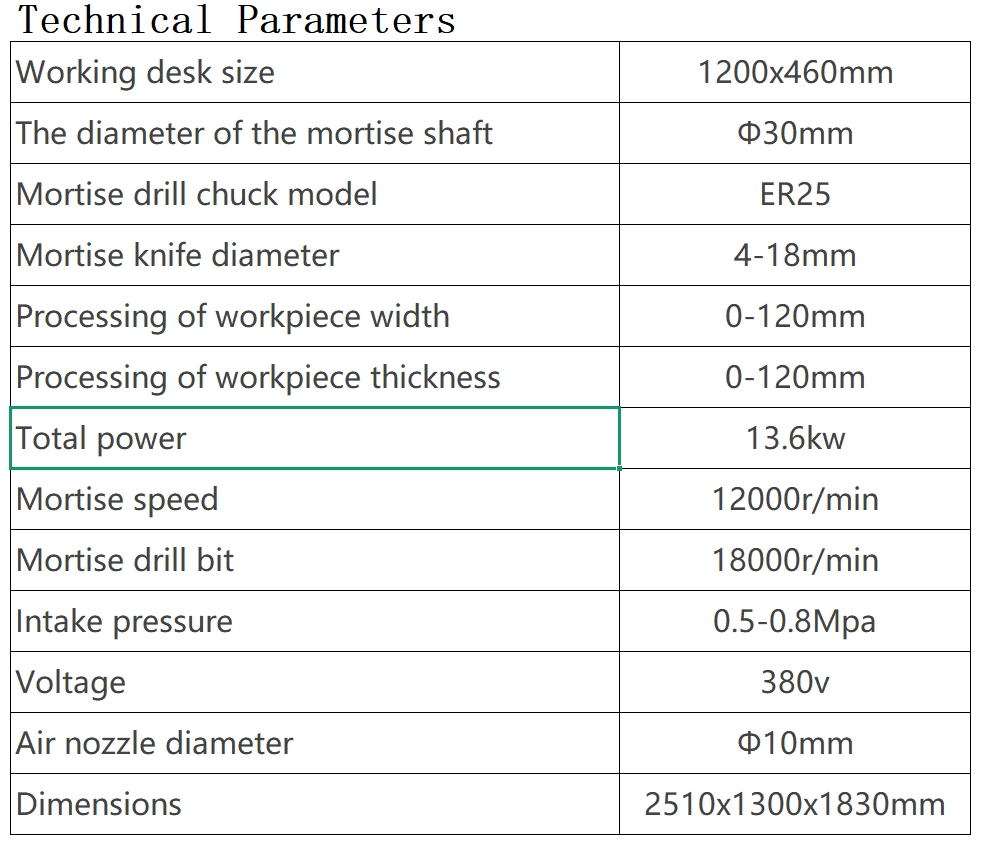

With spindle speeds of up to 18,000 rpm, the JX-ST1200 delivers exceptionally clean and accurate mortises with minimal chipping.

-

-

Versatile Mortise Sizes

-

Capable of handling mortise diameters from 4mm to 18mm, supporting a wide range of joinery types.

-

-

Compact but Powerful

-

Despite its compact footprint, it offers a total power output of 13.6 kW, ensuring consistent power delivery for high workloads.

-

-

Stable Air-Pressure Operation

-

Works with air pressure ranging from 0.5–0.8 MPa, suitable for most factory-standard pneumatic setups.

-

-

Adjustable Processing Range

-

Handles workpieces up to 120mm wide and thick, making it suitable for a variety of chair legs, window blinds, cabinet components, and more.

-

-

Ergonomic Working Table

-

A 1200×460mm large work surface ensures user comfort and precision positioning.

-

Ideal Users / Applications

-

Furniture Manufacturers

-

Especially for chair, table, and cabinet production where mortise and tenon joints are required.

-

-

Wood Component Factories

-

Processing solid wood strips, window blinds, door frames, and similar items.

-

-

Custom Wood Shops

-

Looking for CNC accuracy and batch processing capability in a compact format.

-

-

Joinery Shops

-

Focused on high-precision mortising and interlocking parts for panel and solid wood furniture.

-