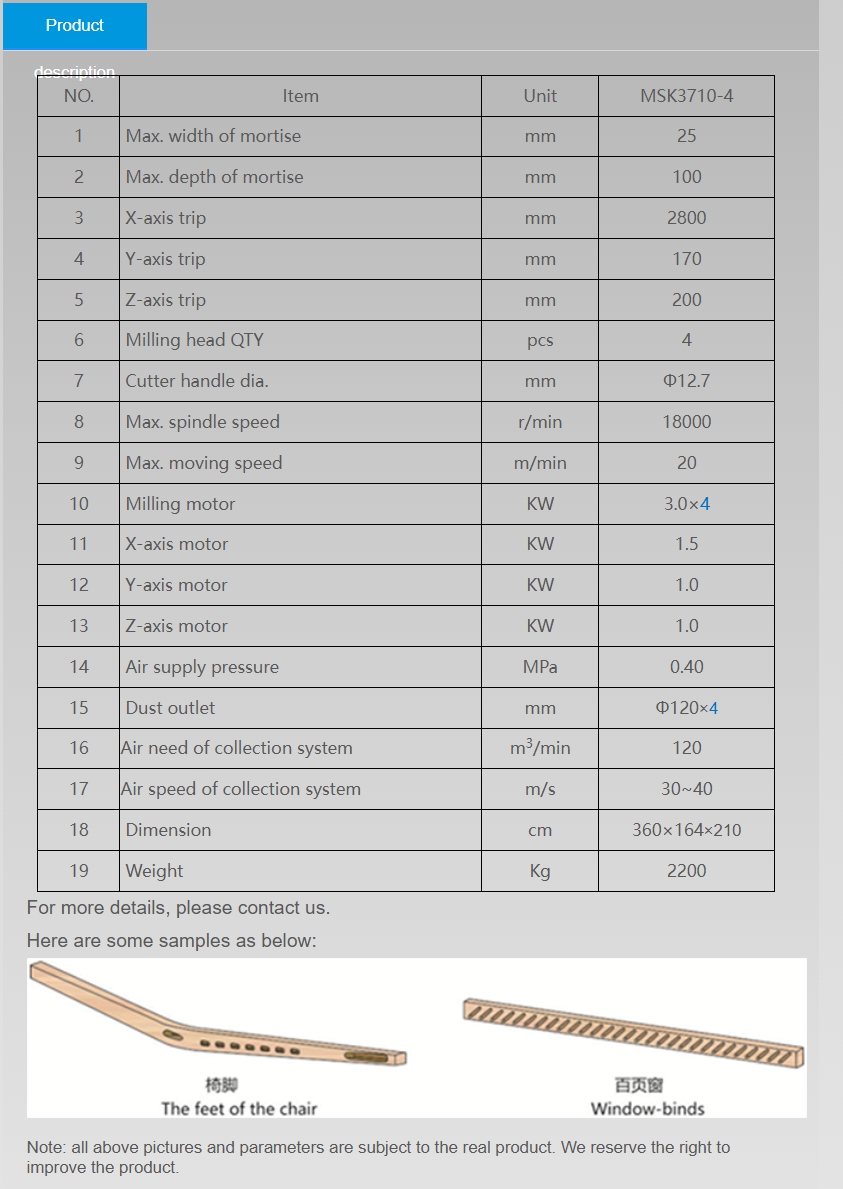

MSK3710-4 CNC Mortising Machine

The MSK3710-4 is a high-performance CNC mortising machine designed for precision milling of complex wooden components such as chair legs, window blinds, and other curved or straight mortise structures. Equipped with 4 independent milling heads, this machine is ideal for high-efficiency, high-accuracy batch production.

Key Features:

-

4-axis CNC control for accurate multi-directional milling

-

Max mortise width: 25 mm

-

Max mortise depth: 100 mm

-

X/Y/Z Axis Travel: 2800 mm / 170 mm / 200 mm

-

Max spindle speed: 18,000 rpm

-

Max feeding speed: 20 m/min

-

Air pressure requirement: 0.4 MPa

-

Efficient dust collection: 4 outlets (Φ120 mm) with 120 m³/min suction volume

Power Configuration:

-

Milling Motors: 3.0 kW × 4

-

X-Axis Motor: 1.5 kW

-

Y/Z-Axis Motors: 1.0 kW each

Machine Dimensions & Weight:

-

Size: 360 × 164 × 210 cm

-

Weight: 2200 kg

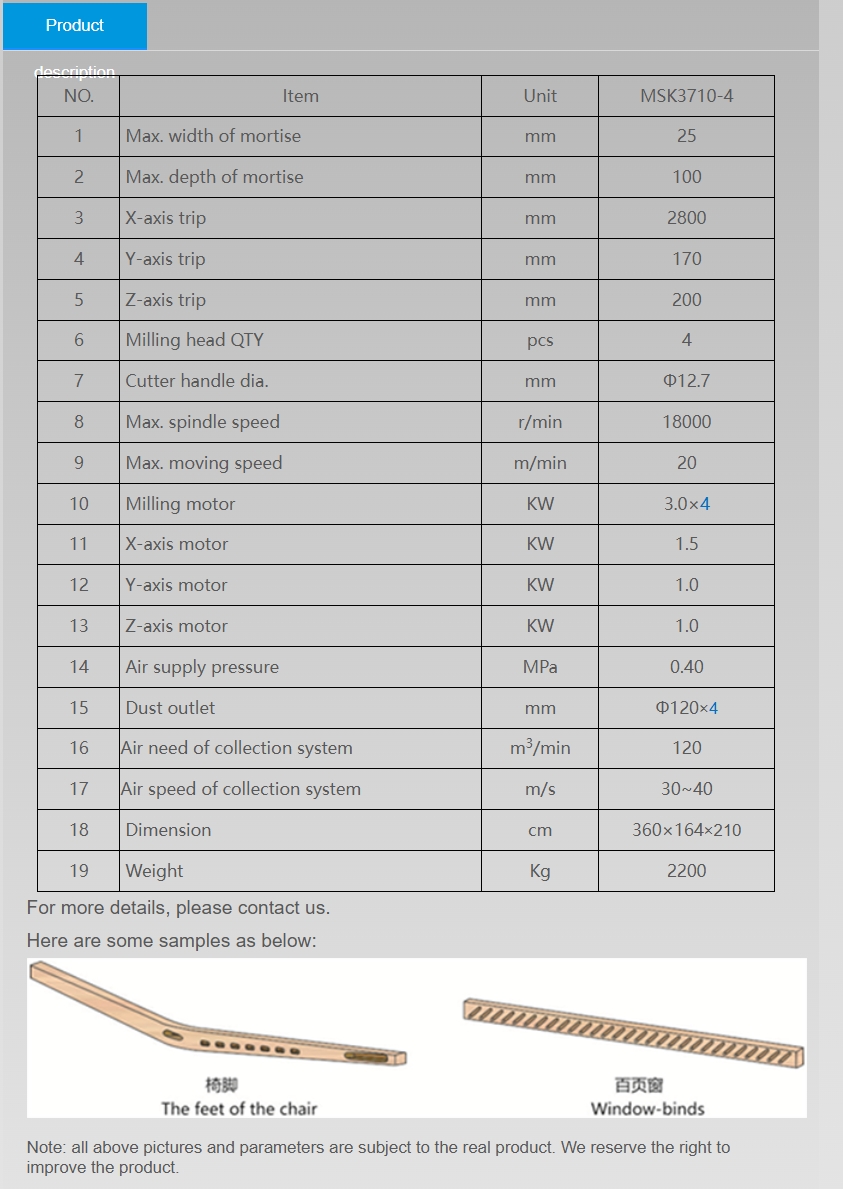

Application Examples:

-

Chair Legs

-

Window Shutters (Blinds)

Who Can Use This Machine?

This machine is ideal for:

-

Furniture manufacturers producing wooden chairs, tables, and cabinets.

-

Door and window manufacturers creating high-precision wooden frames.

-

Wood processing factories requiring mass production of mortises and tenons.

-

Custom woodworking shops looking for automation and efficiency in their production line.