QMB723GH High-Speed Four-Side Moulder

The QMB723GH is a high-performance, 7-spindle four-side moulder designed for heavy-duty, continuous processing in industrial woodworking environments. With powerful motors, advanced feed systems, and a high-speed cutting mechanism, this machine is the ultimate solution for high-efficiency batch production of engineered wood products.

Key Features & Advantages

-

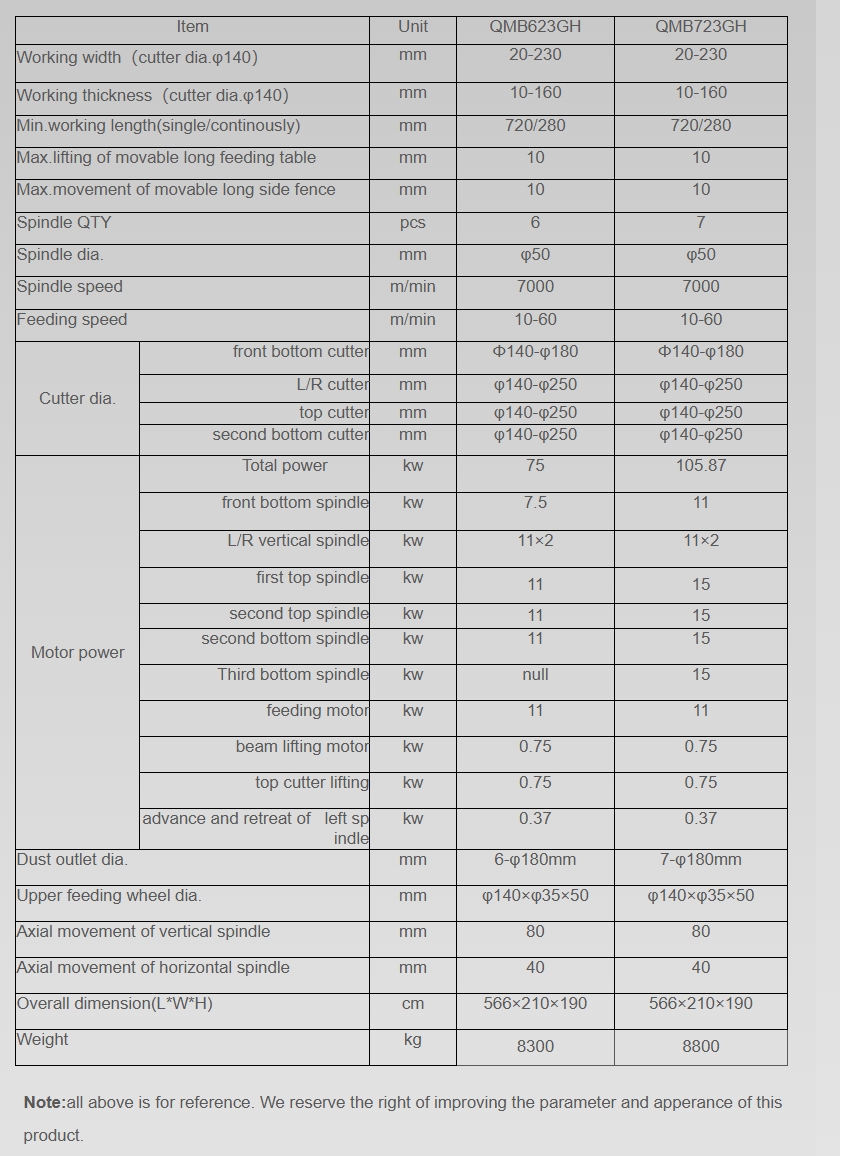

7-Spindle Configuration for Maximum Flexibility

-

Allows complex profiling and simultaneous multi-surface machining in one pass.

-

-

Heavy-Duty, High-Power Build

-

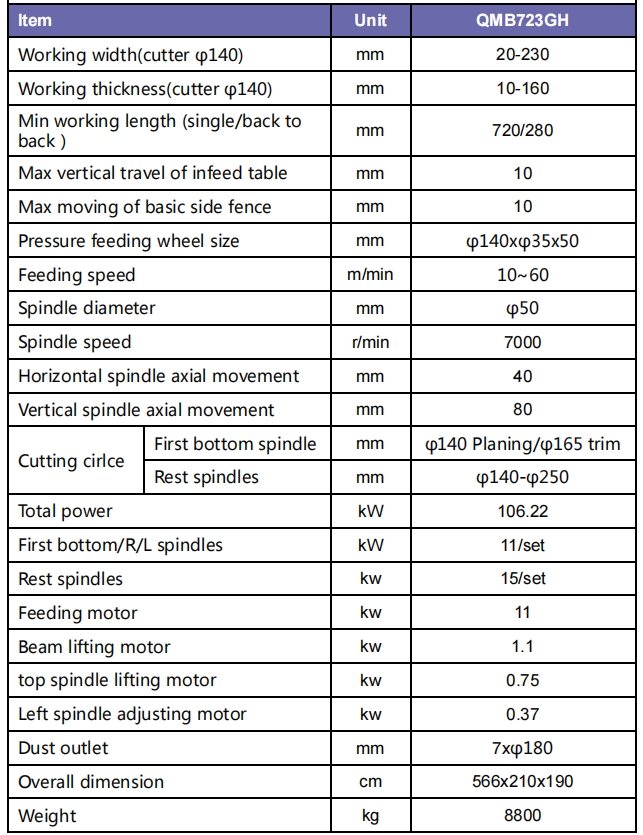

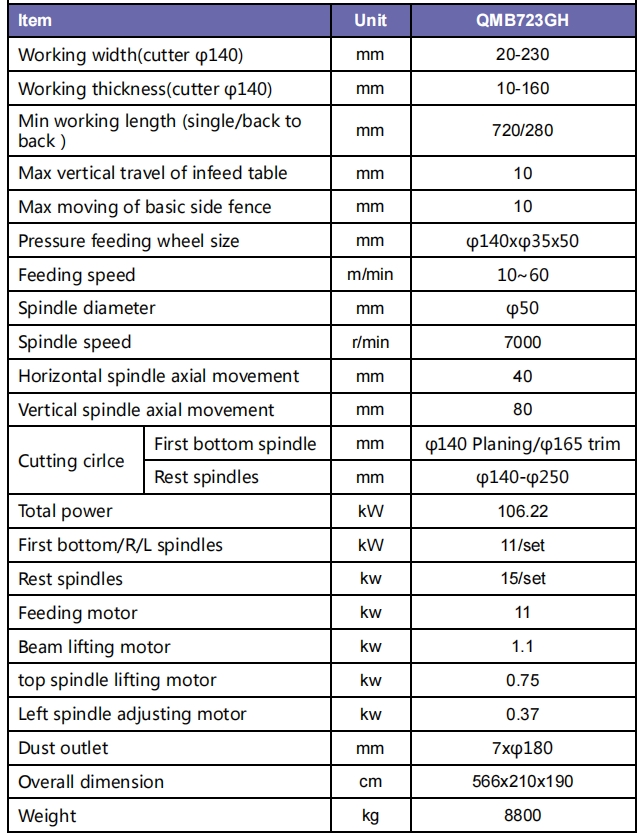

Equipped with 105.87 kW total power and upgraded 15 kW top and bottom spindles, capable of handling large, dense hardwoods with ease.

-

-

High-Speed Throughput

-

Spindle speeds reach up to 7000 r/min, and feeding speed ranges from 10–60 m/min, making it ideal for large-volume, high-precision production.

-

-

Large Capacity

-

Suitable for working widths of 20–230 mm and thicknesses of 10–160 mm, accommodating a wide variety of panel sizes and timber profiles.

-

-

Perfect for Finger-Jointed Boards & Wood Mouldings

-

Designed to tackle continuous processing of laminated finger-jointed panels, moldings, and decorative strips.

-

-

Smart Operation System (Optional CNC)

-

Can be integrated with automated feed and control systems for optimized line production.

-

-

Durable Construction & Dust Control

-

Weighing 8800 kg with 7 large dust outlets (φ180 mm) for clean and safe working conditions.

-

Recommended For

-

Large woodworking factories

-

Engineered wood and moldings manufacturers

-

Mass production of solid wood components

-

Furniture and flooring producers

-

Factories requiring continuous multi-shift operations

Solves:

“Ideal for solving the challenges of high-speed, high-volume production of large finger-jointed panels and wooden molding strips.”