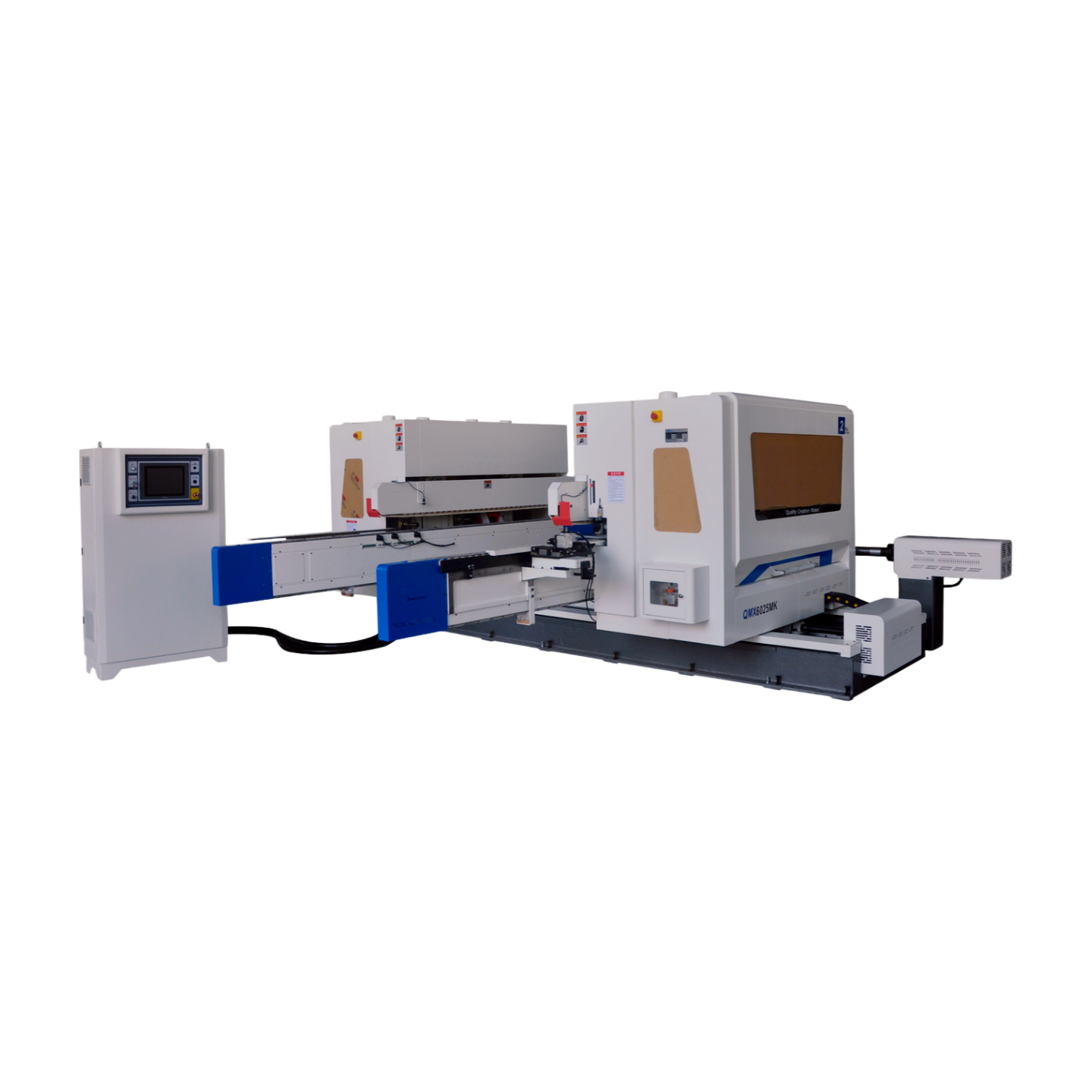

QMX6025MK Three Spine Buckle Double-End Tenoning Machine

Product Overview

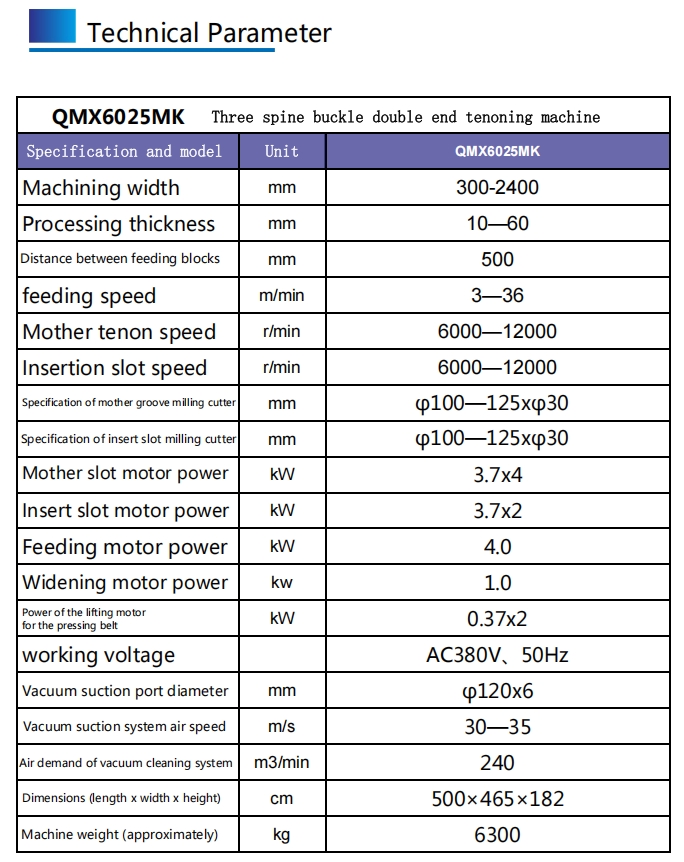

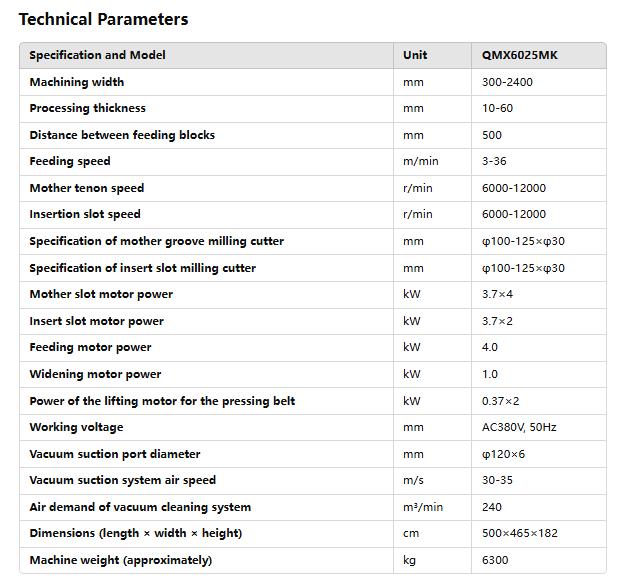

The QMX6025MK is an advanced tenoning machine specifically built for mass production of male tenons on both ends of wooden components. It supports mother tenon cutting and insert slot milling, making it ideal for three-spine buckle type furniture and decorative panel production. Its automated feeding system and high-speed operation help manufacturers boost productivity and ensure consistent machining quality.

Key Features

-

High-Speed Processing: Up to 12,000 r/min for both tenoning and slotting operations.

-

Double-End Machining: Supports simultaneous mother tenon and slot processing.

-

Versatile Milling: Compatible with φ100–125×φ30 tooling for mother and insert slots.

-

Sturdy Build: Heavy-duty structure for stable, long-term performance.

-

Dust Control System: Efficient vacuum setup ensures a clean work area.

-

Automation Friendly: Suitable for assembly line integration with reduced labor requirements.

Who Should Use This Machine?

-

Wood Processing Factories — Ideal for high-volume production of flooring and locking furniture.

-

Furniture Manufacturers — Especially suited for decorative veneer and engineered wood.

-

Large Panel Plants — Excellent for precision slotting in batch production.

-

Design Studios — For producing custom, high-accuracy tenon joints in premium furniture.

Model Comparison: QMX6025GK vs QMX6025MK vs QMX6025M

| Feature | QMX6025GK | QMX6025MK | QMX6025M |

|---|---|---|---|

| Function | Specialized for Three-Spine Buckle Male Tenon processing | Combines male tenon + insert slot cutting in one unit | Standard double-end edge profiling machine |

| Processing Width | 300–2500 mm | 300–2400 mm | 2500 mm |

| Processing Thickness | 10–60 mm | 10–60 mm | 10–120 mm |

| Cutting Speed | 6000–12000 rpm (Pre-cut), 4500–9000 rpm (Milling) | 6000–12000 rpm (Tenon + Insert Slot) | 7500 rpm (Milling), 3000 rpm (Sawing) |

| Key Tools | V-groove + Male Tenon Cutters | Male Tenon + Insert Slot Cutters | Edge milling, bevel cutting, tenoning |

| Feeding Speed | 3–36 m/min | 3–36 m/min | 6–36 m/min |

| Vacuum Suction Port | φ120×8 | φ120×6 | φ120×6 |

| Machine Size (L×W×H) | 485×465×182 cm | 500×465×182 cm | 488×413×189 cm |

| Machine Weight | 6500 kg | 6300 kg | 6000 kg |

| Application | High-precision male tenon machining for flooring and furniture | Integrated production of both tenon and slot for Three-Spine Lock | General wood edge profiling and bevel cutting |

| Best For | Lock flooring, engineered panel tenons | Full Three-Spine buckle production lines | General furniture & flooring factories |

Recommendation by Use Case

| Use Case | Recommended Model |

|---|---|

| Three-Spine buckle (male tenon only) | QMX6025GK |

| Complete three-spine processing (tenon + slot) | QMX6025MK |

| Standard double-end edge profiling & beveling | QMX6025M |