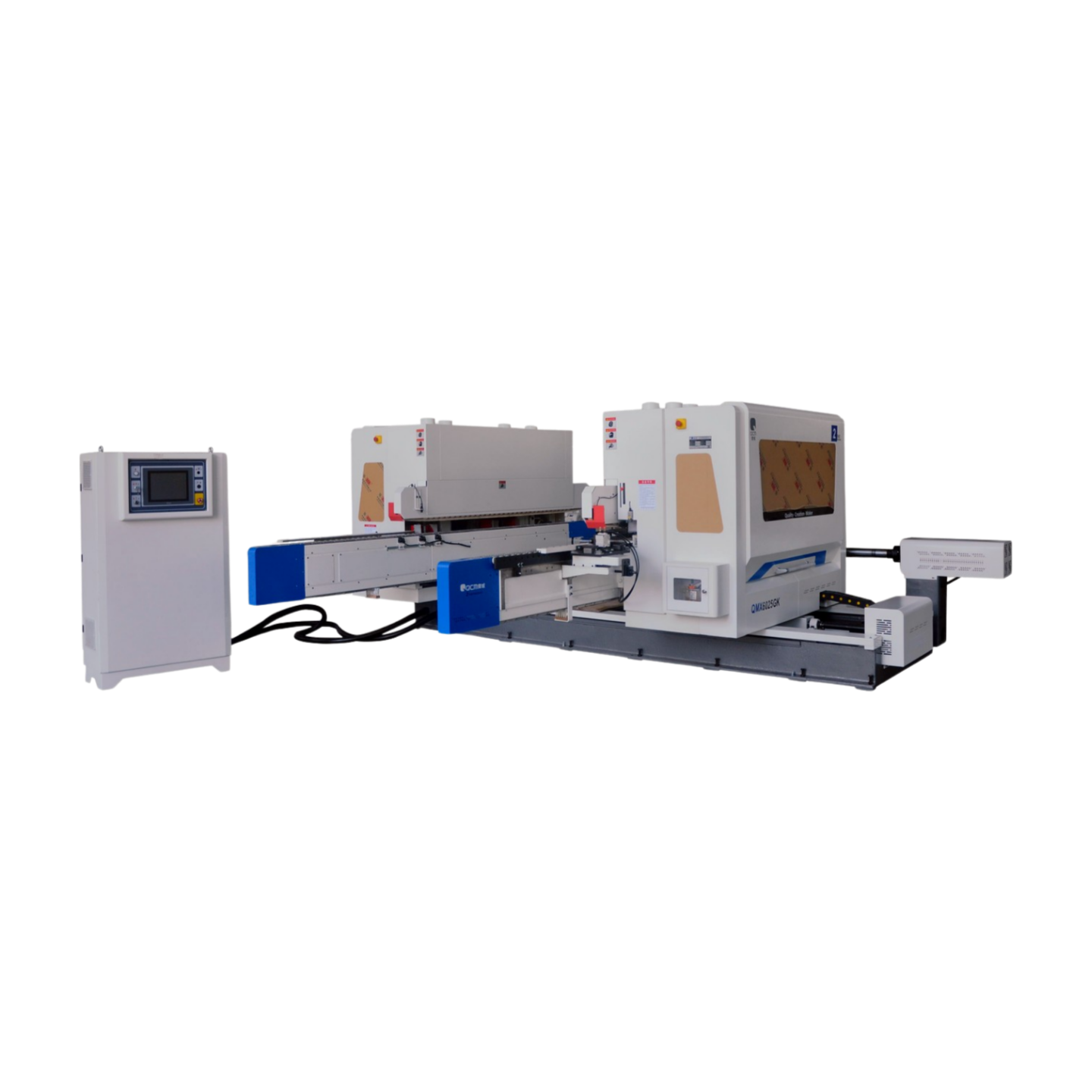

QMX6025GK Three Spine Buckle Double-End Tenoning Machine (Pre-cut & V-Groove Milling)

Machine Overview:

The QMX6025GK is a high-efficiency tenoning machine designed for precise three spine buckle production, offering integrated pre-cut milling and V-groove milling capabilities. Engineered for automated production lines, this machine is ideal for processing solid wood flooring, decorative wood threads, veneer board furniture, and engineered panel components.

Key Advantages:

-

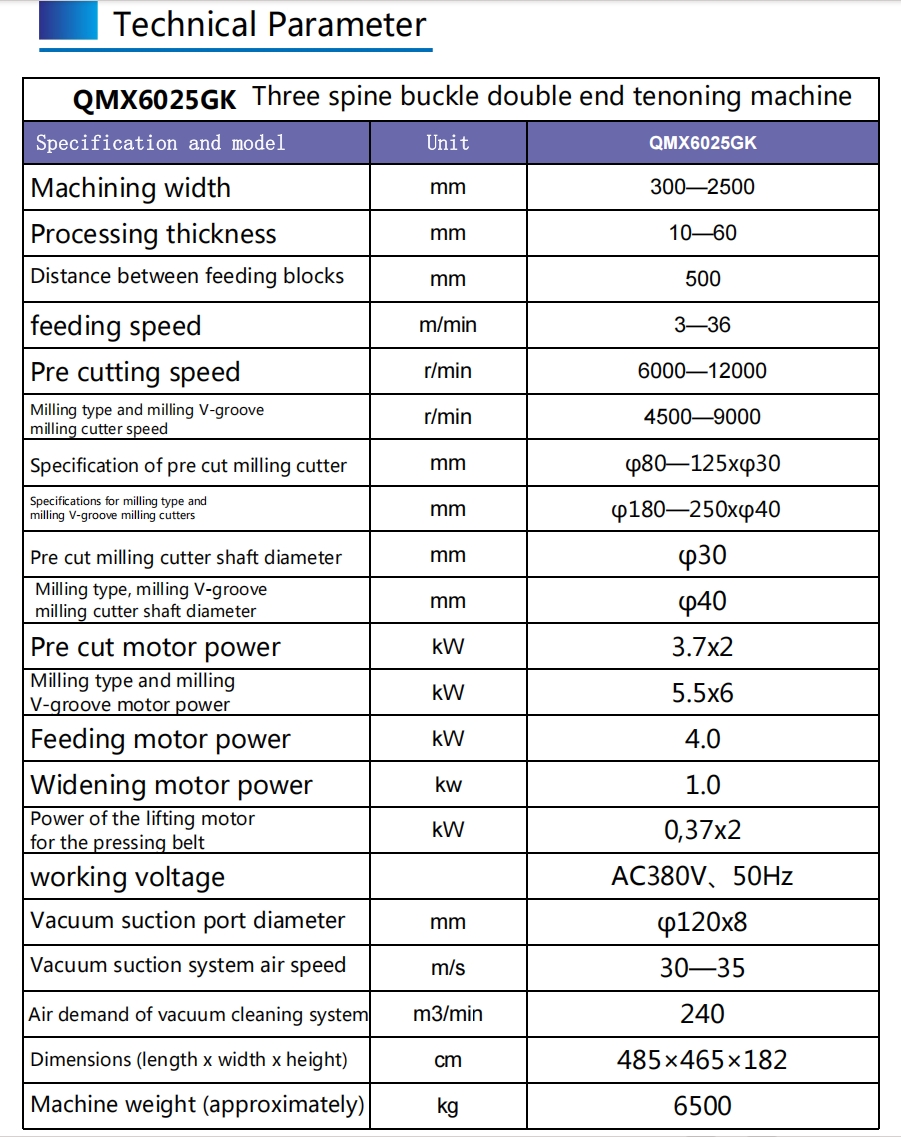

High Efficiency: Supports 24/7 continuous production with stable operation and fast speeds (up to 12,000 rpm).

-

Flexible Milling Functions: Handles both pre-cut milling and V-groove cutting, adaptable to various product structures.

-

Precision Engineering: Equipped with high-speed motors and precise feed control for clean, repeatable tenons.

-

Independent Power Units: Multiple dedicated motors for cutting, feeding, milling, and lifting improve overall system reliability.

-

Dust Management: Includes high-speed vacuum extraction system to maintain a clean processing environment.

Recommended For:

-

Furniture Component Manufacturers – For consistent high-precision tenon production.

-

Solid Wood and Engineered Flooring Plants – Where groove accuracy and durability are essential.

-

Panel Furniture Factories – For complex edge machining including slotting and V-grooving.

-

Mass Production Workshops – Seeking automated, low-labor solutions for large-volume output.

This machine is perfect for factories looking to enhance efficiency, reduce labor dependency, and improve precision in woodworking operations.

Model Comparison: QMX6025GK vs QMX6025MK vs QMX6025M

| Feature | QMX6025GK | QMX6025MK | QMX6025M |

|---|---|---|---|

| Function | Specialized for Three-Spine Buckle Male Tenon processing | Combines male tenon + insert slot cutting in one unit | Standard double-end edge profiling machine |

| Processing Width | 300–2500 mm | 300–2400 mm | 2500 mm |

| Processing Thickness | 10–60 mm | 10–60 mm | 10–120 mm |

| Cutting Speed | 6000–12000 rpm (Pre-cut), 4500–9000 rpm (Milling) | 6000–12000 rpm (Tenon + Insert Slot) | 7500 rpm (Milling), 3000 rpm (Sawing) |

| Key Tools | V-groove + Male Tenon Cutters | Male Tenon + Insert Slot Cutters | Edge milling, bevel cutting, tenoning |

| Feeding Speed | 3–36 m/min | 3–36 m/min | 6–36 m/min |

| Vacuum Suction Port | φ120×8 | φ120×6 | φ120×6 |

| Machine Size (L×W×H) | 485×465×182 cm | 500×465×182 cm | 488×413×189 cm |

| Machine Weight | 6500 kg | 6300 kg | 6000 kg |

| Application | High-precision male tenon machining for flooring and furniture | Integrated production of both tenon and slot for Three-Spine Lock | General wood edge profiling and bevel cutting |

| Best For | Lock flooring, engineered panel tenons | Full Three-Spine buckle production lines | General furniture & flooring factories |

Recommendation by Use Case

| Use Case | Recommended Model |

|---|---|

| Three-Spine buckle (male tenon only) | QMX6025GK |

| Complete three-spine processing (tenon + slot) | QMX6025MK |

| Standard double-end edge profiling & beveling | QMX6025M |