QMX8025M Double-End Tenoner (8 Spindles)

Product Overview

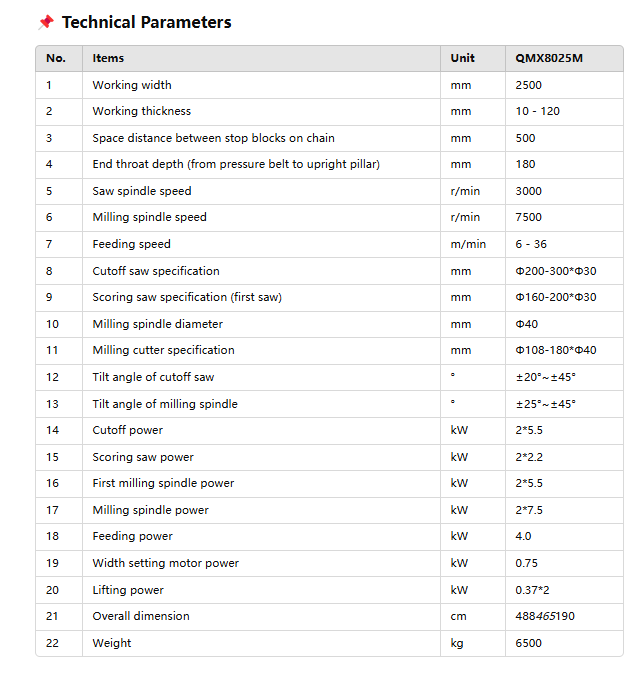

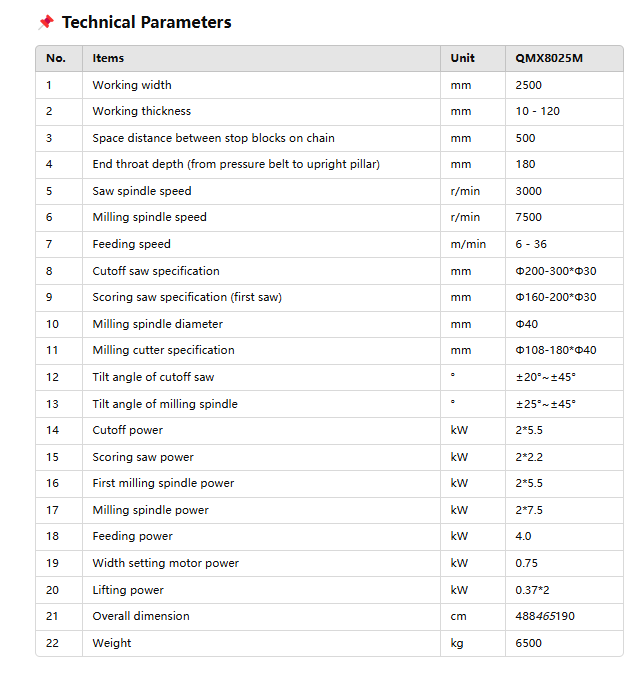

The QMX8025M is a high-performance double-end tenoning and edge trimming machine, specially designed for the efficient processing of solid wood furniture, cabinet doors, board furniture, and other wooden components. With a maximum working width of 2500mm and working thickness up to 120mm, this machine is ideal for handling wide and thick materials with high precision.

Equipped with 8 milling spindles—including two rear spindles that rotate in opposite directions to prevent edge tear-out—the QMX8025M delivers excellent machining results, stable clamping, and high productivity.

Key Features

-

Heavy-duty structure

-

The machine base and frame are made from high-grade castings, machined on a gantry center for enhanced stability and machining accuracy.

-

-

Long feeding table (1300mm)

-

Suitable for large workpieces, ensuring precise positioning and easy handling.

-

-

Advanced feeding system

-

Uses a synchronous chain track with aluminum alloy plates and circular ball bearing guides, offering oil-free, smooth, and precise material feed.

-

-

NC-controlled lifting system

-

Left and right upper beams lift synchronously via NC control, maintaining consistent pressure and simplifying adjustments.

-

-

High-speed milling

-

Spindles are made from special steel and run up to 7500 rpm, delivering high-quality edges with excellent durability.

-

-

Automatic width setting system

-

Uses high-precision linear guides and a motorized controller for easy width adjustments with long-term wear resistance.

-

-

Skip-cutting function

-

The first saw and milling cutter are equipped with automatic skip-cutting to eliminate edge tearing and roughness.

-

-

Top and bottom pressure system

-

Milling sides include flat support bars and cylinder pressure units for stable feed and balanced pressure during cutting.

-

-

Convertible upper saw

-

The upper saw can switch to bottom cutting for core panel tenoning, with optional support and pressure units.

-

-

Extended throat depth

-

Designed to accommodate long tenons and adjustable milling angles via elevated pillars.

-

Frequency-controlled feed drive

-

Equipped with a powerful reducer and frequency converter for adaptive feeding based on material type.

-

Intelligent control

-

Combined PLC and touch screen control for fast setup and minimal downtime.

-

Premium components

-

Uses international electrical and transmission brands (e.g., Siemens) for reliability and longevity.

-

Fully enclosed safety design

-

Ensures operator safety while minimizing noise levels.

-

Optional crushing cutter

-

Breaks up offcuts for easier dust extraction and cleaner operation.