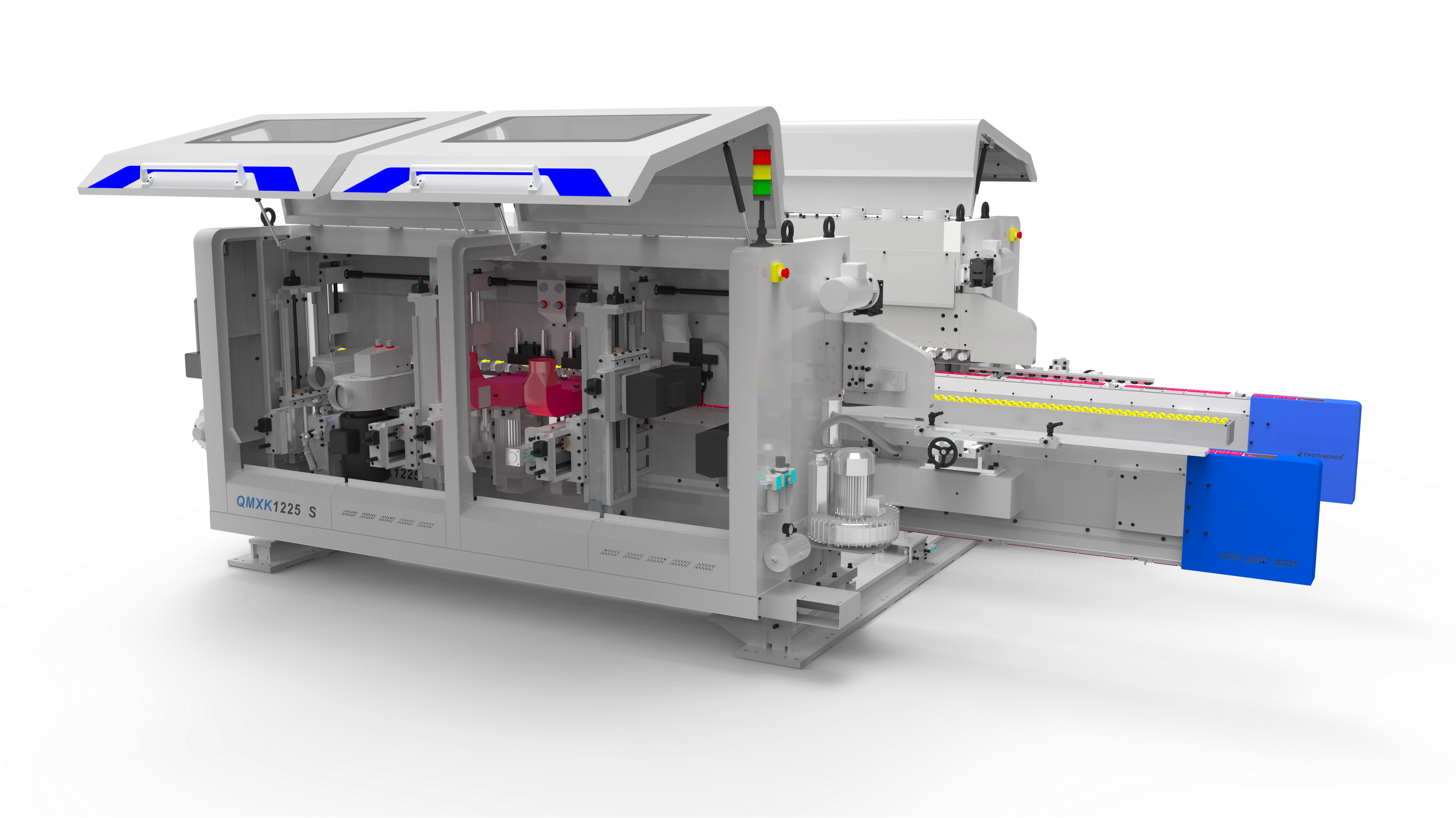

QMX1225S Double-end Saw Milling Sanding Machine

Machine Overview

The QMX1225S is a multi-function double-end processing machine that integrates sawing, milling, and sanding in one. It is designed for high-precision wood processing, ensuring a smooth surface finish and accurate profiling. This machine is perfect for large-scale woodworking industries that require efficiency and high-speed operations.

Key Advantages

• Multi-functional Processing.

Combines sawing, milling, and sanding in a single operation, reducing production time and improving efficiency.

• High-Speed Performance.

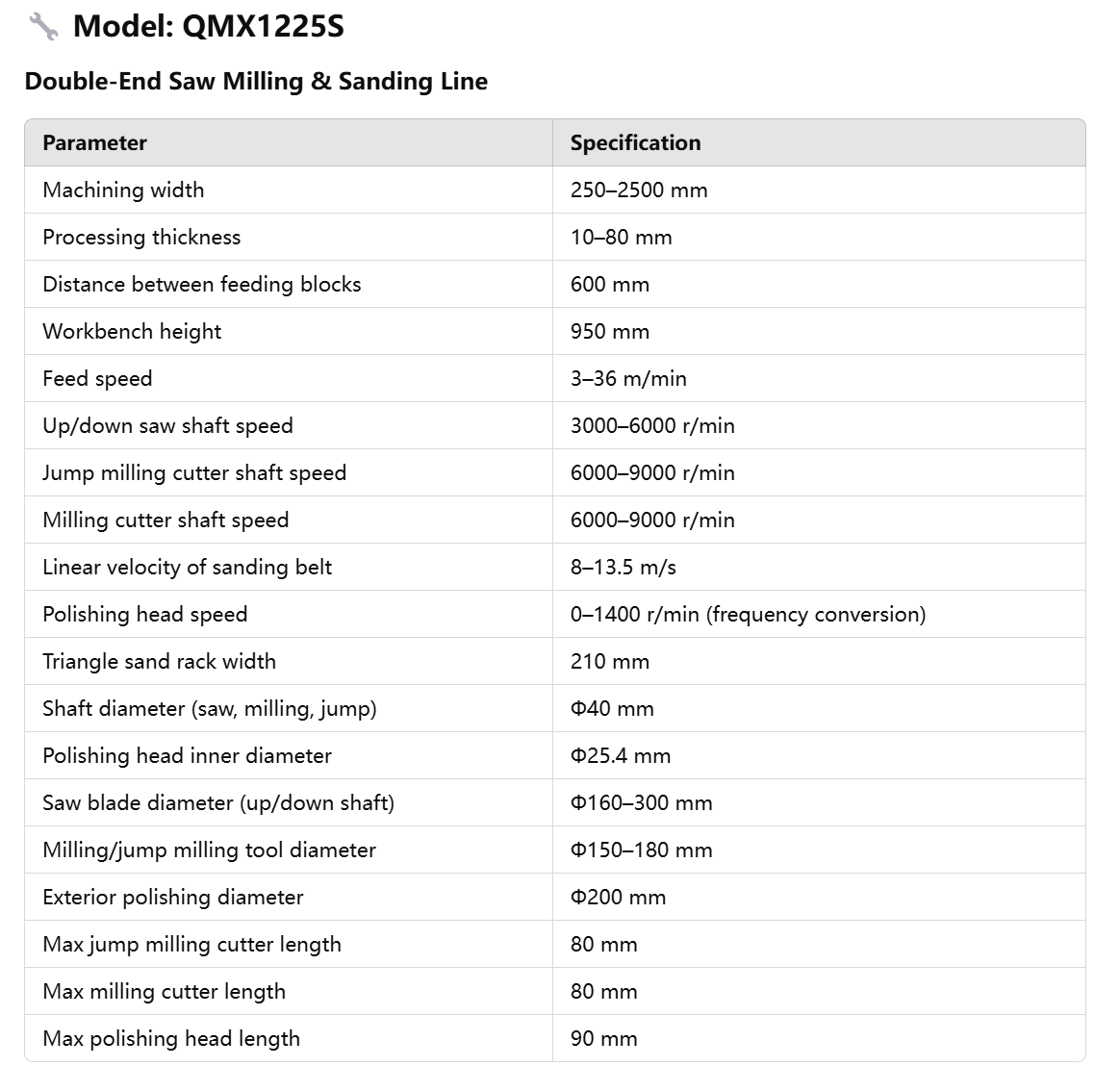

With a feed speed of 3~36 m/min and milling cutter speeds up to 9000 r/min, it ensures rapid and precise processing.

• Versatile Material Handling.

Can handle workpieces with widths from 250mm to 2500mm and thicknesses from 10mm to 80mm.

• Advanced Sanding System.

Equipped with polishing head speeds up to 1400 r/min for a smooth, refined finish.

• Robust Power System.

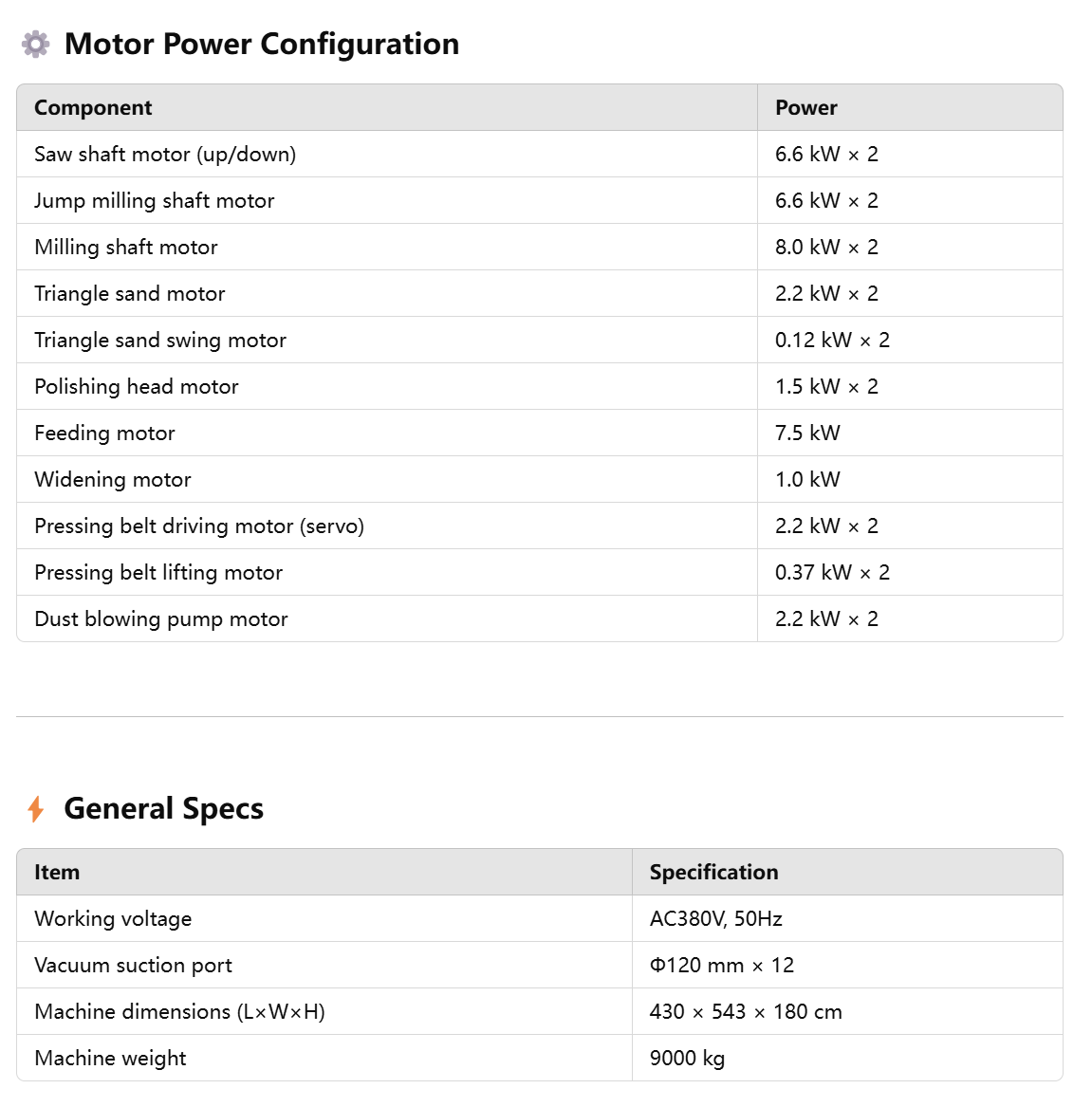

Multiple high-power motors ensure stable and reliable operation.

• Automated Processing.

Servo motor-driven pressing belt for consistent material feeding and precision output.

• Industrial-Grade Construction.

Heavy-duty machine weight (9000kg) ensures stability and durability in high-volume production settings.

Who Should Use This Machine?

• Large-scale furniture manufacturers.

Ideal for processing doors, panels, cabinets, and flooring.

• High-end wood processing plants.

Suitable for decorative woodwork and premium finish requirements.

• Factories with automated production lines.

Integrates seamlessly into automated manufacturing setups to enhance productivity.

• Companies specializing in profiling & edge sanding.

Ensures precise edge milling and smooth surface finishing.